Pilz

PNOZ yh1 2DI 24VDC

- U1 - System power: 24 V DC

- Operating voltage range: 18...30 V DC

- Current consumption: ≤ 100 mA

PSSu H PLC2 FS SN SD

- Ambient temperature: 0 - 60 °C

- Humidity: 93% r.h. at 40 °C, no condensation

- Operating height: 2000 m

- EMC: EN 61000-6-2, EN 61000-6-4, EN 61131-2 (Zone B)

- Vibration: EN 60068-2-6

- Shock: 1150 m/s²

- Clearance & creepage distance: EN 61131-2, overvoltage category II, pollution degree 2

PSSu E F 4DI

- Number of digital inputs: 4

- DC voltage at input: 24 V DC

- Potential isolation inputs: Yes

PSSu E F 4DO 0.5

- Terminal voltage for inductive loads off: U2 - 50 V

- Permitted loads: Resistive, Inductive, Capacitive, Semiconductor outputs

- DC voltage at output: 24 V DC

- Potential isolation short circuit: Yes

- Output short circuit proof: Yes

PSSu E F 2DOR 8

- Acc. shock to standard: 1150 m/s²

- Acc. shock to standard2: 2

- Clearance & creepage dist. to: EN 61131-2

- Overvoltage category: II

3 built-in buttons: ACT1 (green), ACT2 (red) and RESET (yellow)

Button size: 22 mm

Pressing force: max. 10 N

Button stroke: max. 5 mm

Ambient temperature: -20°C to +50°C

Ambient humidity: 35% to 95% (non-condensing)

Vibration resistance: Corresponds to DIN EN 60068-2-6

Impact resistance: Corresponds to DIN EN 60068-2-7

Maximum switching power: 48 W

Minimum switching power: 0.5 W

Leakage current: < 10 μA

Trigger time: < 20 ms

Trigger time: < 10 ms

Operating frequency range: 0 - 1000 Hz

Electrical strength: 2000 V AC/DC

Nominal voltage: 24 V DC

Maximum current: 2 A per key

Switching power: 48 W per key

Contact type: SPST (single pole, single throw)

Contact resistance: ≤ 1 Ohm

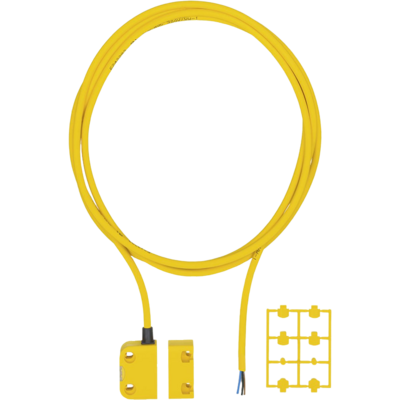

PSEN 2.1p-21/PSEN 2.1-20 /8mm/LED/1unit

- Nominal voltage: 24 V DC

- Current consumption: ≤ 10 mA

- Reverse polarity protection: yes

- Overcurrent protection: yes

- EMC: EN 61000-6-2, EN 61000-6-3

PSEN 2.2p-21/PSEN2.2-20/LED/8mm 1unit

- Nominal supply voltage: 24 V DC

- Current consumption: ≤ 10 mA

- Trigger time: ≤ 10 ms

- Reset time: ≤ 10 ms

- Reverse polarity protection: Yes

- Short circuit protection: Yes

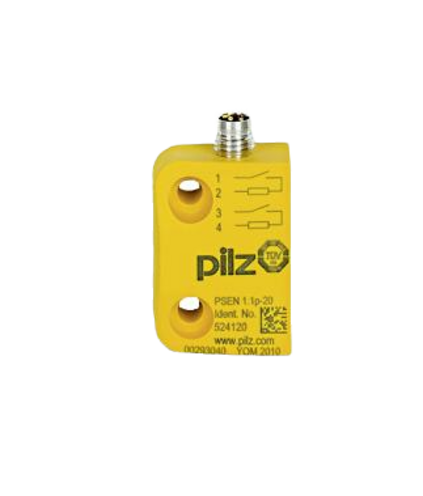

PSEN 1.1p-23/PSEN 1.1-20/8mm/ATEX/ 1unit

- Nominal voltage: 24 V DC

- Maximum power: 4.8 W

- Current consumption: < 10 mA

- Trigger time: < 10 ms

- Reset time: < 10 ms

- Switching range: > 2 mm

- Electrical strength: 2000 V (RMS)

- Insulation resistance: > 100 MΩ

PSEN 1.2p-20/PSEN 1.2-20/8mm/ 1unit

- Output current: max. 2 A

- Load capacity: max. 100 W

- Reverse polarity protection: Yes

- Short circuit protection: Yes

- Impact resistance: IK07

- Vibration resistance: according to DIN EN 60068-2-64

PSEN ma1.4a-51/ 1switch

- Switching voltage: 24 V DC

- Maximum switching current: 2 A DC

- Current consumption: ≤ 10 mA

- Trigger time: ≤ 20 ms

- Reset time: ≤ 10 ms

- Electrical strength: 2500 V AC

- Insulation resistance: ≥ 20 MΩ

PSEN ma1.4p-51/ 1switch

- Actuation force: ≤ 10 N

- Trigger stroke: 8 mm

- Mechanical stability: > 10,000,000 cycles

- Reverse polarity protection: Yes

- Short circuit protection: Yes

- Switching range: 0.5 mm

PSEN ma1.4a-50/PSEN ma1.4-10mm/ 1unit

- Maximum current: 50 mA

- Switching voltage: max. 250 V AC/DC

- Switching current: max. 2 A

- Voltage drop: max. 2 V

- Trigger time: < 10 ms

- Release time: < 10 ms

- Electrical strength: 2000 V AC

- Insulation resistance: > 10 MΩ

PSEN ma1.4a-51/PSEN ma1.4-10mm/ 1unit

- Current consumption: < 100 mA

- Trigger time: 2 ms

- Relay contacts: 2 x NO, 1 x NC

- Maximum switching load: 2 A DC

- Electrical resistance: 1000 V AC/DC

- Insulation resistance: > 20 MΩ

PSEN ma1.4p-50/PSEN ma1.4-10mm/ 1unit

- Maximum switching current: 2 A

- Maximum switching voltage: 250 V AC/DC

- Minimum switching current: 100 mA

- Electrical resistance: ≥ 20 million cycles

PSEN ma1.4p-51/PSEN ma1.4-10mm/ 1unit

- Nominal voltage: 24 V DC

- Nominal current: 2 A

- Power consumption: ≤ 2.5 W

- Trigger time: ≤ 10 ms

- Reset time: ≤ 10 ms

- Electrical resistance: ≥ 1000 V

- Switching range: ≤ 200 V / 2 A

- Actuation force: ≤ 10 N

- Trigger stroke: ≥ 10 mm

- Back stroke: ≥ 8 mm

PSEN ma1.4n-50/PSEN ma1.4-10mm/ 1unit

- Nominal voltage: 24 V DC

- Nominal current: 2 A

- Switched power: ≤ 60 W

- Trigger time: ≤ 10 ms

- Reset time: ≤ 5 ms

- Reverse polarity protection: Yes

- Short circuit protection: Yes

PSEN ma1.4-51M12/8-0.15m/PSENma1.4-10/1u

- Actuation force: 20 N

- Reset force: 10 N

- Shaft diameter: 8 mm

- Permissible angle of rotation: ± 15°

- Shaft material: stainless steel

- Body material: ABS plastic

PSEN ma2.1p-31/LED/6mm/1switch

- Actuation force: ≤ 10 N

- Trigger stroke: 6 mm

- Triggering distance: ≥ 10 mm

- Maximum movement speed: 2 m/s

- Degree of rigidity: M8

PSEN ma2.1p-10/PSEN2.1-10/3mm/1unit

- Actuation force: < 10 N

- Maximum operating frequency: 50 Hz

- Nominal current: < 100 mA

- Current consumption: < 1 A

- Maximum switching current: 2 A

- Switching voltage: 24 V DC

- Trigger time: < 10 ms

- Reset time: < 10 ms

- Reverse polarity protection: Yes

- Short circuit protection: Yes

PSEN ma2.1p-11/PSEN2.1-10/LED/3mm/1unit

- Supply voltage: 11.5...29 V DC

- Current consumption: < 100 mA

- Output current: 2 A DC

- Output type: NO + NC

- Trigger time: < 10 ms

- Reset time: < 10 ms

- Reverse polarity protection: yes

- Overload Protection: Yes

- Sensor material: stainless steel

- Operating temperature: -20°C...+55°C

PSEN ma2.1p-31/PSEN2.1-10/LED/6mm/1unit

- Coding level (ISO 14119): Low

- Classification (EN 60947-5-3): PDB (Safety Disconnect Device)

- Suitable for serial connection: Yes

PSEN ma1.1p-10/3mm/1switch

- Actuation force: ≤ 10 N

- Trigger stroke: 3 mm

- Trigger distance: 10 mm

- Maximum trigger speed: 2 m/s

- Maximum acceleration: 20 m/s²

- Impact resistance: 30 g

PSEN ma1.1p-12/3mm/ix1/1switch

- Nominal supply voltage: 10...30 V DC

- Power consumption: < 10 mA

- Switching voltage: max. 250 V AC/DC

- Maximum switching current: 2 A DC

- Output signal type: 1 NO contact

- Trigger time: 10 ms

- Reset time: 10 ms

- Reverse polarity protection: yes

- Short circuit protection: yes

PSEN ma1.1p-10/PSEN1.1-10/3mm/1unit

- Reverse voltage: 18 V DC

- Reverse current: < 20 mA

- Trigger time: < 10 ms

- Reset time: < 10 ms

- Electrical strength: 2500 V AC

- Insulation resistance: > 20 MΩ

- Actuation force: < 10 N

- Reset force: < 10 N

- Vibration frequency: up to 200 Hz

PSEN ma1.1p-12/PSEN1.1-10/3mm/ix1/1unit

- Actuation force: ≤ 10 N

- Reset force: ≤ 10 N

- Trigger stroke: 3 mm

- Reset stroke: 3 mm

- Vibration: EN 60068-2-6

- Impact: EN 60068-2-7

- Body: Aluminum

- Actuator: Plastic

PSEN 2.1p-21/8mm/LED/1switch

- Nominal voltage: 24 V DC

- Nominal current: 2 A

- Current consumption: ≤ 10 mA

- Electrical strength: 2500 V (RMS)

- Insulation resistance: > 20 MΩ

Pilz is a global leader in industrial automation and safety technology, known for its groundbreaking innovations and unwavering commitment to protecting people, machines and the environment. Headquartered in Ostfildern, Germany, Pilz has been at the forefront for over seventy years, constantly setting the standard for safety and technological advancement.

Pilz was founded in 1948 by Hermann Pilz in Esslingen, Germany. Initially, the company focused on glass laboratory equipment and mercury relays. The transition to electronic control and monitoring systems marked the beginning of Pilz's journey into the world of automation.

Over the years, Pilz has grown from a small family business into a global enterprise with subsidiaries and branches in more than 40 countries. This international presence enables Pilz to provide local support and expertise to customers worldwide, ensuring that its innovative solutions are available worldwide.

Pilz Product Overview

Pilz offers a wide range of components for automation and security in the industry, which are characterized by high quality, reliability and innovation.

PNOZ Safety Relays

PNOZ Safety Pilz relay a fundamental component in industrial automation systems designed to monitor and ensure the safety of machinery and operators. They act as fail-safe devices that trigger an immediate and safe shutdown of machinery in case of a detected fault or hazardous situation.

Characteristics of the PNOZ safety relay:

- Reliability: PNOZ relay pilz is designed and tested in accordance with the most stringent safety standards, ensuring trouble-free operation in critical situations.

- Flexibility: A wide range of modules allows you to choose a solution that is ideal for any application, from simple to complex.

- Ease of use: Pilz safety relay easy to install, configure and maintain.

- Range of functions: PNOZ relays offer a wide range of functions, including emergency stop control, door and safety fence control, and flexible safety control.

- Certification: PNOZ relays are certified in accordance with all major international safety standards.

PNOZ safety relays are used in a wide range of industries including:

- Automotive industry: Conveyors, robotics, welding

- Packaging industry: Packaging machines, conveyors, palletizers

- Food industry: Processing equipment, conveyors, filling lines

- Woodworking industry: Saws, milling machines, planers

- Printing industry: Printing machines, cutting machines, folding machines

Advantages of using PNOZ safety relays:

- Increased safety: PNOZ relays help protect workers from machine hazards.

- Increased productivity: Reduce downtime associated with injuries and accidents.

- Compliance: PNOZ relays help businesses comply with all applicable machine safety regulations.

- Cost reduction: Reduce costs associated with injuries and accidents.

PNOZmulti Small Controllers

PNOZmulti Small Controllers are versatile, modular control systems used for managing safety and automation tasks in industrial environments. These controllers are highly configurable and can handle multiple safety functions within a single system.

Main characteristics:

- Safety level: PL e according to EN ISO 13849-1 and SIL CL 3 according to IEC 62061

- Modularity: A wide range of I/O and expansion modules allows you to flexibly configure the system to meet your needs

- Ease of use: Programming with the intuitive PNOZmulticonfig software

- Temperature range: -20°C to +55°C

- Certification: TÜV, UL, CSA

- Applications: Conveyors, packaging machines, woodworking machines, presses, robotic systems and more

Benefits:

- Increased flexibility and scalability: Modular design makes it easy to add or remove functionality as your needs change.

- Reduced design time and costs: Simple programming and a wide range of modules allow for fast and cost-effective security system implementation.

- Reduced downtime risk: High levels of safety and reliability help prevent accidents and downtime.

- Increased productivity: Effective safety systems allow machines to operate at maximum speed without compromising safety.

Models:

- PNOZmulti Mini: Compact controllers for simple applications

- PNOZmulti Classic: Universal controllers for a wide range of applications

- PNOZmulti Pro: Powerful controllers for complex applications with additional functions

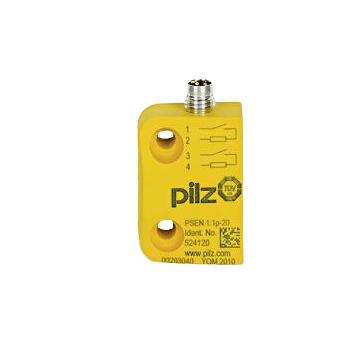

PSEN Safety switches

PSEN Safety Switches are devices used to monitor the position of movable guards, gates, and covers. These switches ensure that machinery operates only when these safety barriers are correctly positioned, preventing access to hazardous areas during operation.

Features:

- High level of safety: PSEN safety switches meet the strictest safety requirements and are certified according to international standards such as IEC/EN 60947-1/-5-E.

- Reliability: PSEN safety switches are made of high-quality materials and designed to work in harsh environments.

- Ease of installation and operation: PSEN safety switches are easy to install and operate, making them an ideal choice for a variety of applications.

- Flexibility: PSEN safety switches can be used with different control systems and sensors.

Advantages of using:

- Ensuring personnel safety: PSEN safety switches help prevent workplace accidents by protecting personnel from dangerous machinery and equipment.

- Increased productivity: can help increase productivity by reducing downtime associated with accidents.

- Cost reduction: reduce costs associated with accidents, injuries and equipment damage.

- Regulatory compliance: PSEN safety switches help businesses comply with safety regulations.

The product range includes:

- Magnetic safety switches: These switches are used to protect hazardous areas of machines where people may come into contact with moving parts. They consist of two parts: an activator, which is mounted on the moving part of the machine, and a control unit, which is mounted on the stationary part. When the activator and the control unit are separated, the machine can operate. If the activator and control unit are in the same position, the machine stops immediately.

- Inductive safety switches: These switches work on the principle of induction and do not require physical contact between the activator and the control unit. This makes them ideal for use in dirty or dusty environments.

- Safety switches with a cable: These switches are used to protect hazardous areas of machines where people can gain access to moving parts. They consist of a cable that is connected to a moving part of the machine and a control unit. When the cable is pulled, the machine stops immediately.

- Finger safety switches: These switches are used to protect people's hands from injury. They consist of rubber fingers that compress when they come into contact with moving parts of the machine. When the fingers are compressed, the machine stops immediately.

Benefits of Using Pilz Products in Industrial Automation

Pilz is renowned for its innovative and reliable solutions in industrial automation and safety technology. Utilizing Pilz products offers numerous benefits that enhance safety, efficiency, and productivity in industrial environments.

1. Unparalleled Safety Standards

High Safety Integrity

Pilz products are designed to meet or exceed international safety standards such as EN ISO 13849-1 and IEC 62061. This ensures that machinery and processes operate within safe parameters, significantly reducing the risk of accidents and injuries.

Comprehensive Safety Solutions

From PNOZ Safety Relays to PSEN Safety Switches, Pilz provides a complete range of safety devices that can monitor various functions, including emergency stops, safety gates, and light curtains. This comprehensive approach to safety helps protect both operators and equipment effectively.

2. Reliability and Durability

Robust Performance

Pilz products are built to withstand harsh industrial environments, ensuring long-term reliability and durability. This robust performance translates to lower maintenance costs and reduced downtime, as systems can operate continuously without frequent interruptions.

Diagnostic Capabilities

Many Pilz products come with advanced diagnostic features that provide real-time status updates and fault information. This capability allows for quick troubleshooting and maintenance, further enhancing system reliability.

3. Flexibility and Scalability

Modular Design

Products like the PNOZmulti Small Controllers are highly modular, allowing users to expand and adapt their safety systems as needed. This scalability ensures that safety solutions can grow with your operations, accommodating increasing complexity without requiring a complete overhaul.

Configurable Solutions

Pilz offers configurable safety systems that can be tailored to specific application requirements. The PNOZmulti Configurator software, for instance, enables users to easily design and modify safety functions to suit their unique needs.

4. Enhanced Productivity

Efficient Integration

Pilz products are designed for easy integration into existing automation systems. Their standardized connections and user-friendly interfaces reduce installation time and effort, allowing for quicker deployment and minimizing disruption to operations.

Minimized Downtime

With raeliable performance and quick diagnostic capabilities, Pilz products help minimize unplanned downtime. Efficient fault detection and resolution ensure that any issues are swiftly addressed, keeping production lines running smoothly.

5. Advanced Technology

Cutting-Edge Innovations

Pilz continuously invests in research and development to stay at the forefront of industrial automation technology. Their products incorporate the latest advancements, such as integrated safety functions in motion control systems and smart, connected devices that support Industry 4.0 initiatives.

User-Friendly Software

Pilz provides powerful software tools like PAScal and PASvisu, which simplify the configuration, programming, and visualization of safety and automation systems. These intuitive tools enhance the user experience and streamline system management.

Pilz products deliver exceptional benefits in industrial automation, including top-tier safety standards, unmatched reliability, and versatile solutions tailored to various applications. With advanced technology and user-friendly interfaces, Pilz ensures enhanced productivity and reduced downtime.

Eltra Trade - Pilz distributor a wide array products to meet your automation and safety needs. Our knowledgeable managers are always available to answer your questions and assist you in selecting the right product tailored to your production requirements. With our expertise and commitment to customer satisfaction, Eltra Trade ensures you receive the best solutions for your industrial automation challenges.