Baumer incremental encoders for general purpose

22.08.2019

Baumer is recognized leader in the field of sensor technology and industrial automation, offering a wide range of products designed to enhance precision and efficiency in manufacturing and processing industries.

Baumer's incremental encoders are designed to convert mechanical motion into electrical signals, providing precise feedback on position, speed, and direction. These encoders come in various types, including hollow shaft, solid shaft, and motor feedback encoders, making them versatile enough to meet the specific requirements of different applications. From simple automation tasks to complex machinery control, Baumer’s incremental encoders offer robust performance, ensuring accuracy and reliability in even the harshest industrial environments.

CONTENTS:

- Incremental encoders series

- Encoders with diameter up to 49mm

- Encoders with housing size 58 mm

- Incremental encoders with large hollow shaft

In industrial automation, precision is paramount. Machines, robots, and automated systems rely on accurate positioning and movement to perform tasks efficiently. This is where encoders come into play, and incremental encoders, in particular, are essential in ensuring that motion control systems operate smoothly.

Encoders Baumer, provide feedback on the position and speed of rotating components in machines. This feedback allows controllers to make real-time adjustments, ensuring that systems maintain their desired performance levels. Whether it’s controlling the movement of a robotic arm, managing the speed of a conveyor belt, or coordinating complex machinery, incremental encoders offer the necessary data to keep operations running efficiently and accurately.

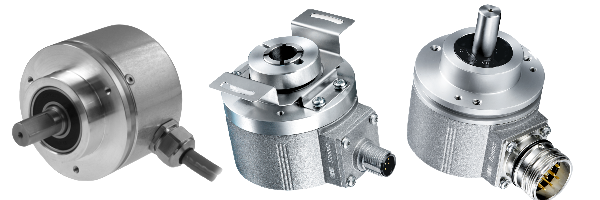

Incremental encoders series

Baumer IVO’s incremental encoders are renowned for their compact dimensions and high precision. Their robust modular design ensures seamless integration with various industrial systems, enhancing operational efficiency and reliability.

Baumer IVO’s incremental encoders are renowned for their compact dimensions and high precision. Their robust modular design ensures seamless integration with various industrial systems, enhancing operational efficiency and reliability.

Baumer IVO offers a diverse range of incremental encoders tailored to meet both general-purpose and specialized application needs. The primary distinctions among the models lie in their operating principles and installation methods.

Types of Incremental Encoders:

- Compact Encoders (Diameter up to 49 mm): Ideal for applications requiring minimal space without compromising accuracy.

- Standard Encoders (Housing Diameter of 58 mm): Versatile and widely used in various industrial applications.

- Large Hollow Shaft Encoders: Suitable for applications requiring the encoder to fit over large shafts, providing flexibility in installation.

- Sine/Cosine Encoders: Offer high-resolution feedback for precise motion control applications.

- Industrial Inch Size/Square Flange Encoders: Designed to meet specific industrial standards and mounting requirements.

- Euro Flange Reo Encoders: Conform to European flange standards, ensuring compatibility with European machinery.

Each category of encoders not only varies in size but also incorporates unique features tailored to specific industrial needs.

- General-Purpose Sensors

General-purpose incremental encoders from Baumer IVO are engineered to deliver reliable performance across a broad spectrum of applications. These encoders are characterized by their:

- High Resolution: Ensuring precise measurement and control.

- Robust Construction: Designed to withstand harsh industrial environments.

- Ease of Integration: Compatible with a wide range of industrial equipment, facilitating straightforward installation and maintenance.

Encoders with diameter up to 49mm

Encoders with a diameter of up to 49 mm are designed to optimize workspace without compromising performance. These compact sensors are available in both solid and hollow shaft configurations and operate on either optical or magnetic principles.

Baumer offers a range of encoders with housing diameters up to 49 mm, including:

- ITD 01 B14: Optical, solid shaft

- ITD 01 A4: Optical, blind hollow shaft

- BDK 16: Optical, solid shaft

- BHK 16: Optical, hollow shaft

- BRIV 30: Magnetic, solid shaft

- BRIV 30R: Magnetic, solid shaft

- BRIH 40: Magnetic, hollow shaft

Optical Encoders

Optical encoders in this category feature robust housings with diameters ranging from 24 to 49 mm. These devices are known for their high precision and reliability. Key specifications include:

- Solid Shaft Diameter: Ø4 - 5 mm

- Hollow Shaft Diameter: Ø4 - 12 mm

- Resolution: Up to 2048 pulses per revolution (ppr)

Optical encoders are ideal for applications requiring high accuracy and are commonly used in environments where precise position feedback is critical.

Magnetic Encoders

Magnetic encoders, while generally less accurate than their optical counterparts, offer superior durability and reliability. These encoders are particularly suited for harsh environments and applications where robustness is essential. Key specifications include:

- Solid Shaft Diameter: 5, 6, and 8 mm

- Hollow Shaft Diameter: Ø6 or 12 mm (BRIH 40 model)

- Resolution: Up to 1024 ppr

Magnetic encoders in this range utilize EcoMag technology, which enhances their resilience through robust magnetic sensing mechanisms. This makes them an excellent choice for applications where long-term reliability and resistance to environmental factors are crucial.

Encoders with housing size Ø58 mm

Encoders with a housing diameter of 58 mm known for their robust all-metal construction. These encoders are available in both optical and magnetic variants, catering to different application needs and shaft types.

Optical Encoders

The Baumer incremental encoders Ø58 family includes several series, each designed for specific applications:

EIL580-SC (Optical Solid Shaft)

- Features: Equipped with a clamping flange and a Ø10 mm shaft.

- Applications: Ideal for precise positioning tasks requiring high accuracy.

- Technology: Utilizes OptoPulse technology for ultra-high accuracy across a wide temperature range.

- Resolution: Up to 65,536 pulses per revolution (ppr).

EIL580-SY (Optical Solid Shaft)

- Features: Comes with a synchronic flange and a 6 mm shaft.

- Applications: Suitable for resilient mounting in dynamic environments.

- Technology: OptoPulse technology ensures consistent performance.

- Resolution: Up to 65,536 ppr.

EIL580-B (Optical Blind Hollow Shaft)

- Features: Designed for applications where the shaft does not pass through the encoder.

- Applications: Commonly used in motor feedback systems.

- Resolution: Up to 65,536 ppr.

EIL580-T (Optical Through Hollow Shaft)

- Features: Allows the shaft to pass completely through the encoder.

- Applications: Ideal for applications requiring easy installation and removal.

- Resolution: Up to 65,536 ppr.

Magnetic Encoders

The magnetic encoders in the Ø58 mm family offer robust performance in harsh environments:

BRIV 58K (Magnetic Solid Shaft)

- Features: Solid shaft design with high resistance to shock and vibrations.

- Applications: Suitable for heavy-duty applications.

- Resolution: Up to 2048 ppr.

BRIV 58S (Magnetic Solid Shaft)

- Features: Similar to BRIV 58K but optimized for different mounting configurations.

- Applications: Versatile use in various industrial settings.

- Resolution: Up to 2048 ppr.

BRIH 58S (Magnetic Hollow Shaft)

- Features: Hollow shaft design with a maximum diameter of 12 mm.

- Applications: Ideal for applications requiring a hollow shaft for cable routing or other purposes.

- Resolution: Up to 2048 ppr.

BRID 58S (Magnetic Through Hollow Shaft)

- Features: Through hollow shaft design for easy integration.

- Applications: Suitable for applications needing a through-shaft configuration.

- Resolution: Up to 2048 ppr.

Mounting and Design

All encoders in this category are designed for radial mounting, ensuring ease of installation and maintenance. The solid shaft models use either synchro or clamping flanges, while the hollow shaft models offer flexibility with different shaft diameters.

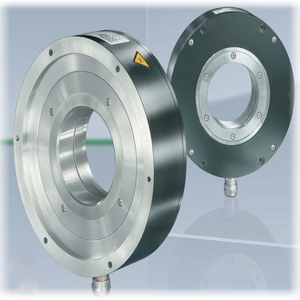

Incremental encoders with large hollow shaft

Incremental encoders with large hollow shafts are specifically engineered for applications involving devices with substantial shaft diameters, such as medium to large AC motors. These encoders are integral to precise motion control and feedback systems in industrial automation.

Baumer Encoder Series with Large Hollow Shafts

Baumer offers a comprehensive range of incremental encoders designed to accommodate large hollow shafts.

- ITD 40

The ITD 40 series is known for its compact design and high precision. It offers resolutions up to 80,000 ppr, making it ideal for applications requiring accurate position feedback. The robust construction ensures reliable performance even in demanding environments.

- ITD 41

The ITD 41 series builds on the strengths of the ITD 40, adding enhanced durability and higher resolution options. It’s perfect for medium to large AC motors, providing excellent signal stability and easy installation with its through-hollow shaft design.

- HS35F

The HS35F series stands out with its rugged design and high shock and vibration resistance. This makes it suitable for heavy-duty industrial applications. It also features a wide range of hollow shaft diameters and optional torque support for added mechanical stability.

- ITD 61

The ITD 61 series offers a balance of high resolution and robust performance. It’s designed for applications that require precise speed and position control. The series includes models with shaft isolation to prevent electrical interference, ensuring reliable operation.

- ITD 70

The ITD 70 series is characterized by its high resolution and versatile mounting options. It supports a wide range of hollow shaft diameters and includes features like torque support and shaft isolation. This series is ideal for precision machinery and high-speed motor applications.

- ITD 75

The ITD 75 series is the top-of-the-line option, offering the highest resolution and most advanced features. It includes models with enhanced environmental protection, making it suitable for harsh industrial conditions. The series also supports the largest hollow shaft diameters, providing flexibility for various applications.

Key Features and Specifications

- Optical Measurement Principle: All models utilize high-precision optical sensing technology, ensuring exceptional signal quality and process stability.

- High Resolution: These encoders provide resolutions up to 80,000 pulses per revolution (ppr), enabling precise position and speed measurements.

- Hollow Shaft Diameter: The encoders support hollow shaft diameters ranging from 17 mm to 85 mm, making them versatile for various industrial applications.

Additional Features

- Torque Support: Some models include torque support to enhance mechanical stability and reduce wear.

- Shaft Isolation: Certain units feature shaft isolation to prevent electrical interference and ensure reliable operation.

Design and Installation

The design of these encoders emphasizes simplicity and ease of installation. The through-hollow shaft configuration allows for direct mounting onto the drive shaft, saving space and reducing installation time. This design also facilitates quick and straightforward maintenance.

Conclusion

Baumer’s extensive portfolio includes 21 series of incremental encoders, catering to a wide range of industrial needs. This variety ensures that customers can select the most suitable encoder for their specific application, whether it involves high-speed motors, precision machinery, or harsh environmental conditions. The inclusion of advanced features such as torque support and shaft isolation further enhances their suitability for demanding applications.

Eltra Trade offers a comprehensive range of Baumer incremental encoders to suit diverse applications. Our knowledgeable team is always ready to assist you in selecting the perfect encoder for your specific requirements. Experience our reliable and swift delivery, and be amazed by our unbeatable prices. Find the perfect Baumer encoder for your requirements!