Baumer sensors: perfect for accurate object recognition

11.09.2018

Baumer is a name that stands out in the world of industrial automation, has consistently demonstrated its ability to innovate and evolve, keeping pace with the ever-changing demands of the industry. What sets Baumer apart is its dedication to precision engineering and a relentless pursuit of perfection. This is reflected in their extensive product range, which is designed to cater to the diverse needs of industries worldwide.

In today’s industrial landscape, where precision and reliability are critical, Baumer sensors play a pivotal role. Whether it’s detecting the presence of minute components on a production line, ensuring the proper assembly of parts in automotive manufacturing, or verifying the integrity of packaging in food and beverage processing, Baumer sensors deliver the accuracy that is vital to maintaining high standards of quality.

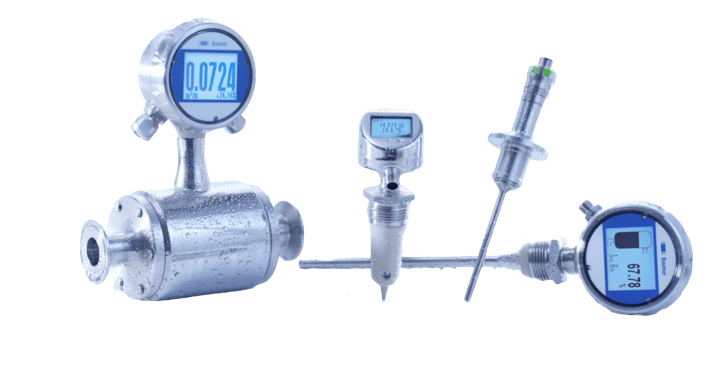

One of the most impressive aspects of Baumer sensors is their versatility. They offer a range of sensors—optical, ultrasonic, inductive, and capacitive—each designed to excel in specific applications. This flexibility allows them to be used across a wide spectrum of industries, from heavy-duty manufacturing to precision-driven fields like pharmaceuticals and electronics.

Types of Sensors by Baumer

Leading the way in sensor technology worldwide, Baumer provides a wide array of solutions to meet the needs of different industrial and automation applications. Their sensor portfolio can be broadly categorized into the following types:

1. Object Detection Sensors

- Baumer Inductive Proximity Switches: Within a certain range, these sensors pick up the presence of metal objects. Their strength, longevity, and high switching frequencies are well known.

- Baumer photoelectric sensors: Use light beams to identify things according to their distance, color, or opacity. They are highly versatile and precise, making them appropriate for a wide range of applications.

- Baumer Ultrasonic Sensors: These ultrasonic sensor baumer use sound waves to identify things independent of their material qualities and calculate distance. They are frequently employed in hostile settings.

- Baumer Capacitive Sensors: Sensors pick up capacitance variations brought on either conductive or non-conductive materials being close by. They are perfect for spotting non-metallic objects, bulk materials, and liquid levels.

2. Position Sensors

- Linear Position Sensors: These sensors measure linear displacement, offering precise position feedback for various applications like robotics and automation.

- Rotary Position Sensors: These sensors measure angular displacement, providing accurate rotational position information for motors, valves, and other rotary components.

- Inclination Sensors: Sensors measure the angle of inclination or tilt, used in applications like leveling, stabilization, and machine orientation.

- Pressure Sensors: Provide absolute and relative pressure readings in a range of units, including bar, psi, and mbar. They are employed in environmental monitoring, process automation, and fluid control.

- Temperature Sensors: These temperature sensors provide precise measurements for applications such as safety, environmental monitoring, and process control.

3. Force and Torque Sensors

- Baumer Force Sensors: These sensors measure force, providing feedback for load monitoring, process control, and quality assurance.

- Baumer Torque Sensors: Measure torque, used in powertrain control, robotics, and machine monitoring.

- Baumer Level Sensors: These sensors are used in process industries and storage applications to detect the level of liquids, solids, or bulk materials in containers or tanks.

- Baumer Flow Sensors: These sensors, which are used in process control, metering, and environmental monitoring, measure the flow rate of liquids or gases.

4. Other Sensors

- Baumer Vibration Sensors: These vibration sensors are used for problem detection, condition monitoring, and predictive maintenance.

- Baumer Acceleration Sensors: These sensors, which are utilized in navigation, safety systems, and motion control, monitor acceleration.

- Baumer Humidity Sensors: These sensors measure relative humidity, used in climate control, food processing, and environmental monitoring.

Key Features by Baumer

Baumer, a leading sensor technology provider, incorporates a range of advanced features across its product line to enhance performance, reliability, and user experience. While specific features may vary depending on the sensor type and model, some common key features offered by Baumer include:

1. Performance Features

- High Precision and Accuracy: Baumer sensors are renowned for their ability to deliver precise and accurate measurements, essential for demanding applications.

- Wide Measurement Ranges: Covering a broad spectrum of measurement parameters, Baumer sensors can accommodate various process conditions and applications.

- Fast Response Times: Quick response times enable real-time monitoring and control, improving system efficiency.

- Robustness and Durability: Designed to withstand harsh environments, Baumer sensors offer exceptional reliability and longevity.

- High Repeatability: Consistent performance over time ensures reliable and predictable results.

2. Functionality Features

- Digital Output: Many Baumer sensors offer digital output options (e.g., IO-Link, Ethernet) for easy integration into modern automation systems.

- Analog Output: For applications requiring continuous data, analog output options are available.

- Customization Options: Baumer provides flexibility through customizable sensor configurations to meet specific application requirements.

- Self-Diagnostics: Early problem detection is made possible by built-in self-diagnostic features, which save downtime.

- Sensor Fusion: Integrating data from several sensors to improve decision-making and information availability.

3. Connectivity Features

- IO-Link: Seamless integration into digital ecosystems through IO-Link communication for efficient data exchange and device management.

- Ethernet: Advanced connectivity options for high-speed data transmission and remote monitoring.

- Fieldbus Compatibility: Support for various fieldbus protocols to suit different industrial networks.

4. Application-Specific Features

- Shock and Vibration Resistance: For applications in challenging environments, Baumer offers sensors with enhanced resistance to shock and vibration.

- EMI/RFI Immunity: Reliable functioning in noisy conditions is ensured by protection against radio frequency interference and electromagnetic interference.

- IP Ratings: Different degrees of intellectual property protection to shield against environmental elements like water, oil, and dust.

- Wide Operating Temperature Range: Accommodating diverse operating conditions, from extreme cold to high temperatures.

Applications of Baumer Sensors in Industry

Baumer sensors, renowned for their precision, reliability, and versatility, find applications across a vast array of industrial sectors. Their ability to accurately measure and monitor various parameters is instrumental in driving efficiency, productivity, and quality.

1. Manufacturing

- Assembly and Robotics: Utilizing photoelectric, inductive, and capacitive sensors for accurate object detection, positioning, and quality control.

- Process Control: Monitoring and regulation of temperature, pressure, flow, and level for optimized production processes.

- Packaging and Labeling: Accurate product handling, labeling, and inspection through object detection, positioning, and quality control sensors.

2. Automotive Industry

- Production: Streamlined assembly lines, quality control, and component testing through precise sensor-based automation.

- Vehicle Components: Essential for engine management, braking systems, steering, and suspension systems.

3. Food and Beverage Industry

- Process Control: Maintaining exact temperature, pressure, flow, and level monitoring to guarantee product safety and quality.

- Packaging: Accurate filling, sealing, and labeling for efficient and reliable packaging processes.

4. Logistics and Material Handling

- Conveyor Systems: Efficient material flow and sorting through object detection, positioning, and counting sensors.

- Warehouse Automation: Enhanced order fulfillment and inventory control using sensor-based devices and automated guided vehicles (AGVs).

5. Energy and Utilities

- Power Generation: Monitoring and control of critical parameters for efficient and reliable power generation.

- Renewable Energy: Optimizing performance and monitoring conditions for solar, wind, and hydro power systems.

6. Environmental Monitoring

- Water and Wastewater Treatment: Accurate measurement and control of water quality parameters for effective treatment processes.

- Air Quality Monitoring: Precise detection and monitoring of pollutants for environmental protection.

7. Other Industries

- Agriculture: Precision farming, livestock monitoring, and environmental control through sensor-based solutions.

- Healthcare: Medical equipment calibration, patient monitoring, and laboratory automation.

- Building Automation: Energy-efficient building management through temperature, humidity, and occupancy sensing.

As sensor technology develops further, Baumer keeps adding new products to its lineup and helping to provide creative answers to problems facing the industry.

Latest Developments in Baumer Sensors

Baumer consistently pushes the boundaries of innovation to meet the evolving demands of industries worldwide. Recent years have witnessed significant advancements in Baumer sensor technology, focusing on areas such as precision, speed, connectivity, and environmental sustainability.

Enhanced Precision and Accuracy

One of the core focuses of Baumer's research and development is to improve sensor precision and accuracy. This is particularly crucial in applications demanding high levels of detail and reliability. New sensor models boast advanced algorithms and refined sensing elements to deliver exceptionally accurate measurements, even in challenging environments. For instance, in the field of metrology, Baumer has introduced sensors capable of capturing minute variations in dimensions with unprecedented precision.

Increased Speed and Response Time

Making decisions quickly on the basis of real-time data is often necessary in modern industrial operations. Baumer has created sensors with noticeably faster response times in order to remedy this. Faster process control, more efficient production, and improved safety protocols are all made possible by these high-speed sensors. These sensors, for instance, speed up object detection and manipulation in robotics, increasing throughput and precision.

Advanced Connectivity and Integration

The trend towards Industry 4.0 and the Internet of Things (IoT) has driven the need for seamless sensor integration and data exchange. Baumer has responded by incorporating advanced connectivity options into its sensor portfolio. This includes enhanced support for industrial communication protocols like Ethernet, IO-Link, and wireless technologies. These developments enable efficient data transfer, remote monitoring, and predictive maintenance.

Prioritize environmental impact and sustainability

As sustainability becomes a paramount concern, Baumer is actively developing sensors that contribute to eco-friendly practices. Energy-efficient sensor designs, reduced material consumption, and longer product life cycles are key areas of focus. Additionally, Baumer is investing in sensors for environmental monitoring applications, such as air and water quality measurement, to support sustainable development initiatives.

Specific Examples of New Sensor Technologies

- Smart Sensors: Incorporating advanced processing capabilities, smart sensors can perform complex calculations and decision-making directly at the sensor level, reducing data transmission and processing requirements.

- Miniaturized Sensors: Smaller sensor packages enable integration into compact devices and systems, opening up new application possibilities.

- Multi-sensor Fusion: Integrating data from various sensor kinds enhances system performance overall and yields more thorough information.

Due to Baumer's dedication to research and development, its sensor solutions will always be at the forefront of technological innovation. Baumer continues to provide cutting-edge products that promote productivity, sustainability, and efficiency by meeting the changing needs of many sectors.

Conclusion

Baumer sensors stand as a testament to precision engineering, offering unparalleled accuracy in object recognition. Their robust construction, coupled with advanced technologies, ensures reliable performance across diverse industrial settings. From manufacturing and automation to logistics and quality control, Baumer sensors empower businesses to optimize processes, reduce errors, and achieve new heights of efficiency. By selecting the right Baumer sensor for specific application needs, organizations can confidently enhance their operations and gain a competitive edge.

Eltra Trade offers a vast selection of Baumer sensors. As a trusted partner with years of experience, we provide swift global delivery, expert guidance, and competitive pricing. Our dedicated team is ready to assist you in finding the ideal Baumer sensor for your specific needs.