Endress Hauser Proline Promag 400 Fault Codes

14.02.2024

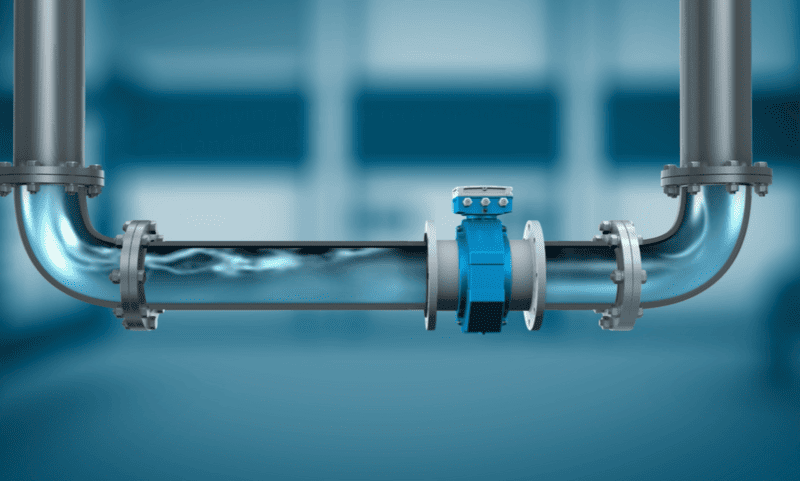

Endress+Hauser is a global leader in measurement equipment, services, and solutions for industrial process engineering. The company provides various products and services to industries such as chemical, petrochemical, oil and gas, water and wastewater, food and beverage, pharmaceuticals, and many others. In particular, the company produces vortex flowmeters. Below we will look at Endress Hauser Promag 400 fault codes in more detail.

Exploring Common Fault Codes and Their Interpretations

Any equipment can become faulty over time. Sometimes, you can see Promag 400 fault codes. But what to do if you find yourself in such a situation? Below, we will look at Promag 400 error codes explanations and methods for eliminating them.

| Error | Causes | Solution |

Local display is dark and there are no output signals | The supply voltage does not match the value indicated on the nameplate. | The supply voltage does not match the value indicated on the nameplate. |

| Local display is dark and no output signals | No contact between connecting cables and terminals. | Check the connection of the cables and correct them if necessary. |

| Local display is dark and no output signals | Terminals are not plugged into the main electronics module correctly. | Check terminals. |

| Local display is dark and no output signals | The main electronics module is defective. | Order spare parts. |

| Local display is dark and has no output signals | The connector between the main electronics module and the display module is not plugged in correctly | The connector between the main electronics module and the display module is not plugged in correctly |

| Local display is dark and no output signals | The connecting cable is not plugged | 1. Check the connection of the electrode cable and correct it if necessary. 2. Check the connection of the coil current cable and correct it if necessary. |

| Local display is dark, but the signal output is within the valid range | The display is set to too bright or too dark. |

|

| Local display is dark, but the signal output is within the valid range | The display module is defective. | Order spare parts. |

| The backlighting of the local display is red | A diagnostic event with "Alarm" diagnostic behavior has occurred. | Take remedial measures. |

| Text on local display appears in a foreign language and cannot be understood. | Incorrect operating language is configured. | 1. Press - and + for 2 s ("home position"). 2. Press E. 3. Set the desired language in the Display language parameter. |

| Message on local display: "Communication Error" "Check Electronics" | Communication between the display module and the electronics is interrupted. |

|

| Signal output outside the valid range | The main electronics module is defective. | Order spare parts. |

| The device shows the correct value on the local display, but the signal output is incorrect, though in the valid range. | Configuration error. | Check and correct the parameter configuration. |

| The device measures incorrectly. | Configuration error or device is operated outside the application. | 1. Check and correct parameter configuration. 2. Observe limit values specified in the "Technical Data". |

Proactive Measures for Preventing Promag 400 Faults

Preventing Endress Hauser fault codes involves implementing proactive measures to ensure its reliable and accurate performance. Here are some recommendations.

Regular calibration

Schedule regular calibration checks according to the manufacturer's guidelines. Calibration ensures accurate measurements, and regular checks can identify issues before they impact performance.

Routine maintenance

Establish a routine maintenance schedule to inspect and clean the flowmeter components. This includes the sensor, electrodes, and other critical parts. Regular maintenance prevents the accumulation of debris or corrosion that can lead to faults.

Environmental monitoring

Monitor and control environmental conditions around the Promag 400. Ensure that the flowmeter operates within the specified temperature, humidity, and pressure ranges. Extreme conditions can affect the device's performance.

Proper installation

Follow the manufacturer's installation guidelines precisely. Ensure correct sensor alignment, proper grounding, and secure wiring connections. Improper installation can lead to measurement inaccuracies and faults.

Regular inspections

Conduct regular visual inspections of the flowmeter and its surroundings. Look for signs of physical damage, leaks, or other abnormalities. Early detection allows for timely intervention.

Firmware upgrade

Stay informed about firmware updates provided by the manufacturer. Upgrading the firmware can improve the device's performance, introduce new features, and address known issues.

Monitoring flow profile

Be aware of the flow profile in the installation location. Ensure that the flow conditions meet the recommended criteria for optimal performance. Irregular flow profiles can affect measurements and lead to faults.

Power quality

Implement measures to stabilize and protect the power supply for the Promag 400. Voltage fluctuations and power interruptions can adversely affect the flowmeter's functionality.

Training and awareness

Ensure that personnel responsible for the Promag 400 are adequately trained on its operation, maintenance, and troubleshooting. Increased awareness can lead to early identification and resolution of potential issues.

Backup power

Consider using backup power sources or uninterruptible power supply (UPS) systems to prevent faults caused by power outages or fluctuations.

Documentation

Maintain thorough documentation of all maintenance activities, calibration checks, and any issues encountered. This documentation can be valuable for tracking the device's history and aiding in future troubleshooting.

Spare parts inventory

Keep a stock of critical spare parts on hand. This ensures prompt replacement in case of component failure and minimizes downtime.

Periodic system audits

Conduct periodic audits of the entire flow measurement system, including associated instrumentation and control systems. Identify and address any issues that may impact the Promag 400's performance.

Tips for Troubleshooting Promag 400 Issues

If you're facing issues with it, here are some expert tips for Endress+Hauser Promag 400 fault codes troubleshooting.

Reference the manual

Consult the user manual for the Promag 400. The manual typically contains Promag 400 diagnostic procedures, error code explanations, and maintenance instructions.

Power supply check

Ensure that the Promag 400 is receiving the correct power supply. Voltage fluctuations or power interruptions can lead to malfunctions.

Wiring and connections

Inspect all wiring and connections. Loose or damaged connections can cause communication issues and inaccuracies in measurements.

Grounding

Verify that the flowmeter is properly grounded. Poor grounding can lead to signal interference and inaccurate readings.

Check sensor alignment

Ensure that the sensor is correctly aligned. Misalignment can affect the accuracy of measurements.

Calibration verification

Perform a calibration check to confirm the accuracy of the Promag 400. Incorrect calibration can result in measurement errors.

Flow profile

Check if there are disturbances in the flow profile. Irregularities in the flow profile can affect the performance of the flowmeter.

Environmental conditions

Consider environmental factors such as temperature, humidity, and the presence of corrosive substances. Ensure that the Promag 400 is installed and operated within specified environmental conditions.

Diagnostic tools

If the Promag 400 has built-in diagnostic tools, use them to identify specific issues. Some flowmeters provide error codes or diagnostic messages that can assist in troubleshooting.

Firmware Updates

Check for firmware updates for the Promag 400. Updating the firmware can address common faults in Promag 400 and improve overall performance.

Examine display and indicator lights

If the Promag 400 has a display or indicator lights, observe them for any unusual behavior or error messages. This can provide valuable information about the nature of the issue.

Consult technical support

If troubleshooting on your own is not successful, reach out to the manufacturer's technical support for assistance. They may provide additional guidance or recommend further steps.

Professional assistance

If the issue persists, consider seeking assistance from a qualified technician or the manufacturer's service center. They have the expertise to diagnose and resolve complex problems.

Eltra Trade offers a wide selection of high-precision measuring devices such as flow meters, level sensors, E+H pressure sensors and temperature sensors from the leading manufacturer Endress+Hauser. Our experienced managers are ready to help you choose the right model. With global shipping and competitive pricing, we ensure our customers get the best value for money.