What is universal electric motor? How does it work with AC/DC sources?

03.06.2020

TABLE OF CONTENTS:

- Universal motor main parts

- How does a universal motor run on DC current?

- How a universal motor works with AC source

- Universal motors vs DC motors (Advantages and disadvantages)

- Where universal motor is used?

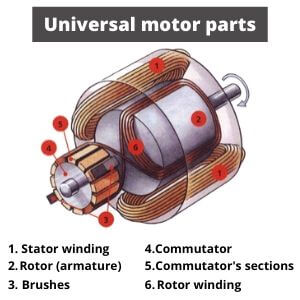

Universal motor main parts

The main design of such motor is almost identical to common brushed DC motor. We described its working principle in the following article: Brushed vs Brushless motor. However, it contains electromagnetic type of magnets instead of permanent ones and has additional options for working with alternating current.

The main parts of its structure are rotor and stator.

Stator is a part that does not move (stationary).

It contains several major details:

- Laminated case

- Field coils

- Wiring from source

- Brushes

Rotor (armature) is a rotating part.

It consists of the following main details:

- Shaft

- Commutator

- Rotor windings

Let's look what makes universal type so special, and describe its operation principle.

How does a universal motor run on DC current?

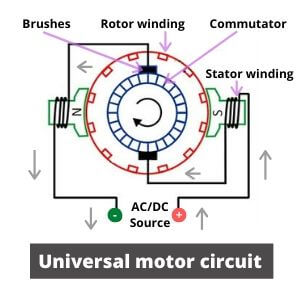

When it is connected to a power source with direct current, it works like a regular DC motor with brushes.

Electricity from the source flows into stator winding (field coils), through the brushes it gets into commutator and then goes to armature coils. Each of the brushes simultaneously is connected to different segments of commutator and electricity through each of them passes in one direction.

Hence, magnetic fluxes will act in one direction too. Rotor’s torque action will also be unidirectional in turn. Therefore, it begins to rotate (on clockwise or counterclockwise way).

In such mode, the electric motor has the highest efficiency. The most similar alternative for working with DC source is a BLDC motor. However, due to the general use of permanent magnets in it, its max torque is much lower than in universal types.

How a universal motor works with AC source

When a universal motor is operated with alternating current, it is also used series winding connection. It links rotor and stator windings (as described above). So, there is no difference between ac and dc universal motor design.

However, in the case of alternating current, it will flow in different directions in opposite coils. That is why the series connection is used. Due to that scheme type, change of the poles and hence magnetic fluxes in windings is performed almost simultaneously.

Since magnetic fluxes act in the same direction, therefore, the action of torque is also unidirectional. Rotor will always rotate in similar way, despite the pulsating current.

However, if you connect an ordinary DC series motor to AC source it will not work. This happens due to fluctuating magnetic field and heavy losses to the Foucault’s eddy currents.

To avoid these phenomena, the stator is made of a set of special thin laminated plates, and the winding is divided into several sections.

Work with alternative current is also induces the electromotive force and extreme sparking on motor brushes. Therefore, the contact brushes should be made of material with high resistance.

Attention! When the motor working with AC, its overall efficiency will be much lower. Therefore, you always need to check the efficiency value in specifications separately for AC and DC.

Ok, how it rotates is clear, but how to change the direction of rotation of universal motor? It’s very simple. To change the rotation direction you just need to reverse the connection of the windings of either the rotor or stator.

Universal motors vs DC motors (Advantages and disadvantages)

Universal motors have several unique design options that is described above. That features give its own pros and cons compared to common DC or induction analogs. Let’s look at them in detail.

The main advantages:

- High starting torque. The mechanism can quickly start to perform extremely high revolution speed (up to 8000 and even up to 20,000 rpm) in both hot and cold starts.

- High power density. It can operate with twice output power value than an inductive analog with the same size.

- Low price. The cost of the motor is little higher than ordinary brushed and quite lesser than brushless.

- Simple design. A simple structure provides ease of maintenance and repair.

- Good lifespan. The main parts are quite durable (except brushes).

- Portability. Its small size allows it to be used in the smallest devices (haird ryer).

- Work without constant monitoring. The motor can be adjusted by simply changing the voltage via frequency converters.

The main disadvantages:

- Noise and vibration. It occurs because the brushes rub on the sections of armature commutator during high speed.

- Low efficiency. Its efficiency is in the range of 55-80% and depends on source type (DC/AC).

- Ineffective with low voltage. The efficiency significantly reduces when working with voltages up to 100V.

- Brushes burn out quickly. Due to the direct contact of the brushes with the collector, they require periodic replacement or repair.

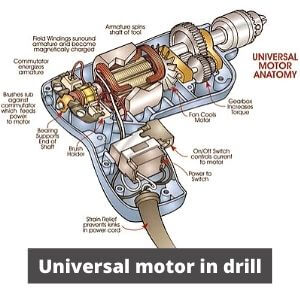

Where universal motor is used?

A universal electric motor, as we have found out, is a simple, inexpensive, and high-speed type of motor.

The ability to operate at extremely high speed connecting to a single-phase AC network made them very popular in domestic appliances. In addition, it has miniature sizes and can be used in compact household devices. In industrial branches, this equipment is also often used, but its effectiveness is not suitable for everyone.

Here are the most common applications:

- Drills and screwdrivers

- Mixers and Blenders

- Fans and hair dryers

- Vacuum cleaners

- Sewing machines

- Wipers

- Washing machines

- Sawmills

Such motor is used primarily in areas where the noise level is not critical but high revolutions are important.

Eltra Trade offers a wide selection of motors from leading companies such as Siemens, Omron, Lenze, and ABB. We provide fast worldwide delivery and the best prices!