- Comprehensive diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Automatic setup of diagnostic system

- Full software integration into PCS and PAM possible

- Diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Plug and play - no engineering required

- For online monitoring

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Alarm limits configurable via DIP switches

- Fault indication transmission by voltage free contact

- Output: 21 ... 23 V/500 mA

- Voltage limitation for Entity ic and Ex nL

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- Output: 28 ... 30 V/500 mA

- High-power trunk for high device count and long cable lengths

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- PROFIBUS DP V1 / For 4 segments PA

- Couples PROFIBUS PA devices transparently to PROFIBUS DP

- Optional redundant configuration

- Installation in Zone 2/Class I, Div. 2

- Up to 12 Mbit/s, auto adapting

- For redundant and non-redundant masters

- Supports Flying Redundancy (FR)

- Cyclic/acyclic data exchange

- Gateway PROFINET RT to 4 x PROFIBUS PA segments

- Up to 32 devices per PROFIBUS PA segment

- Installation in Zone 2/Class I, Div. 2

- Ring and system redundancy

- Integrated webserver for diagnostics

This product is not available now!!!

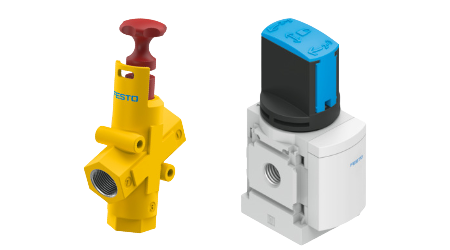

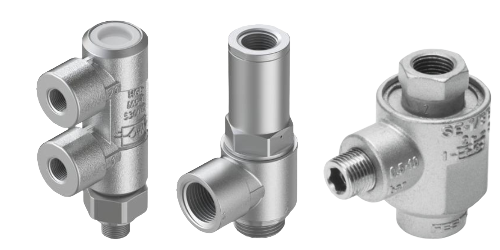

Festo HE-LO

| Pneumatic connection, port 1 | G3/8 |

| Standard nominal flow rate (standardised to DIN 1343) | 5200 l/min |

| Operating pressure | 1 bar - 10 bar |

- Signal level shifting from HTL - TTL or TTL - HTL

- Isolating signal cables to multiple receivers to avoid earth loops

- Regenerating of signals when transmitting over long distance

- 1 input unit and 3 output units

- Converting of SinCos signals into TTL and HTL signals

- Additional interpolation of the signals (multiplying or dividing)

- Oversampling with 24 MHz

- Digitally pre-filter

- Very high output frequency possible

- Converting of SinCos signals into multiplied SinCos signals

- Multiplying factor 1...128

- Offset and amplitude adjustment

- Oversampling with 24 MHz

- Digitally pre-filter

- High signal quality

- Converting of SinCos signals into multiplied SinCos signals

- Additional interpolation of HTL or TTL signals (multiplying or dividing)

- Oversampling with 24 MHz

- Digitally pre-filter

- Very high output frequency possible

Fiber-optic receiver for interference-free transmission of square-wave signals

- For high interference locations

- Each channel is coupled onto fiber-optic easy-to-fit plug

- Reconversion of optical to electrical signals in the receiver control cabinet

- 3 different plug versions available

- Delay time over a 100 m length of fiber-optic is 1 Вµs

- Except of POF all fiber optic cable usable, e. g. PCF 200 Ојm, silica fiber 50 and 62.5 Ојm

art. 11072698

| Input current | 15 mA |

| Inputs | HTL, TTL |

heavy duty cylinder

- Mounting options: front, rear, side, flange, axle

- Rod type: single-acting, double-acting

- Piston type: single action, double action

- Seal material: NBR, FKM, PTFE, EPDM, PU

- Working fluid: air, oil

- External coating: anodizing, powder coating

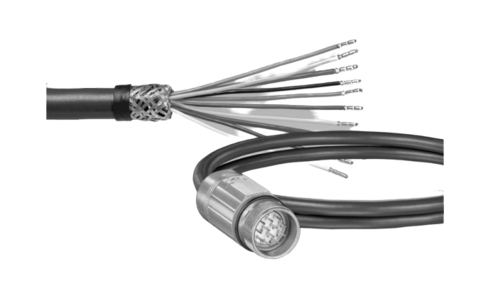

- Test voltage: Wire/conductor: 1500 V ef, Wire/shield: 750 V ef

- Protection: Common low-capacitance shield, shielded paired signal wires

- Weight: Approximately 110 g/m

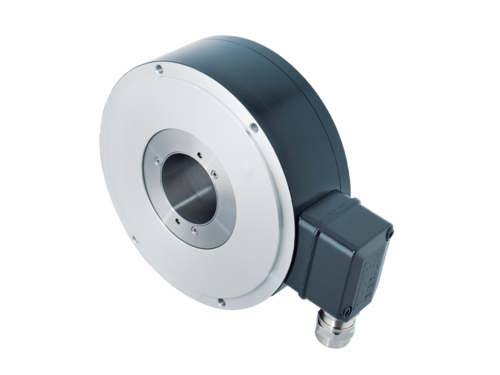

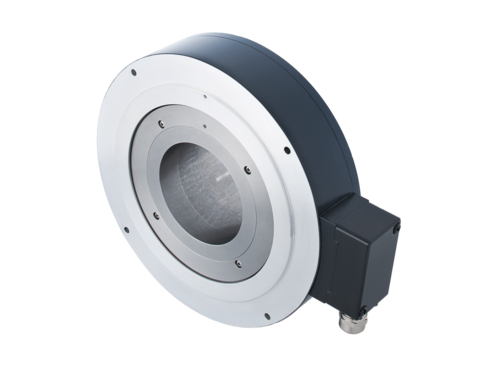

Baumer HG 16

- Incremental encoder with optical sensing

- Large axial and radial displacement of the shaft permitted

- Fit for high operating speed

- Robust and wearless

- Max. 2048 pulses per revolution

- Output stage TTL with regulator UB 9...26 VDC

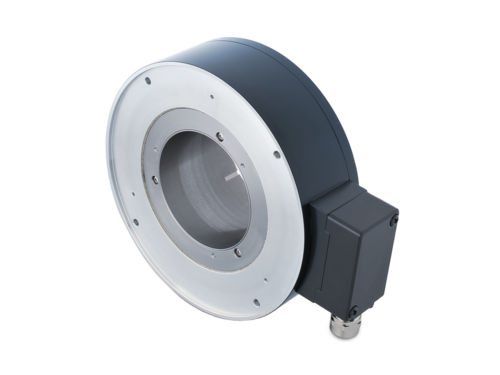

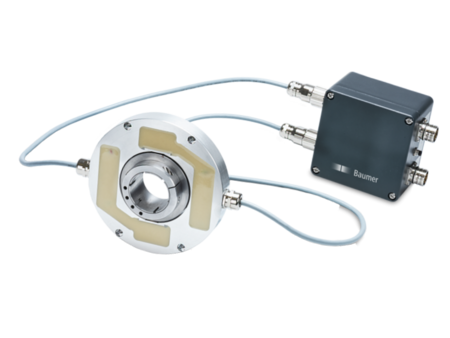

Baumer HG 18

- Incremental encoder with optical sensing

- Fit for high operating speed

- Max. 2500 pulses per revolution

- Output stage TTL with regulator UB 9...26 VDC

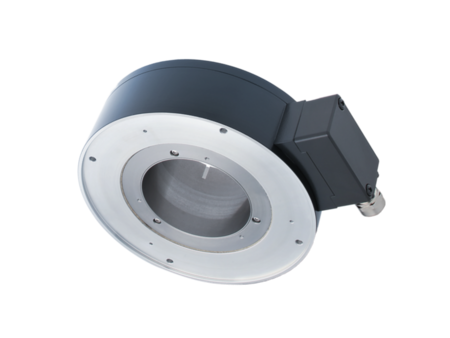

Baumer HG 22

- Incremental encoder with optical sensing

- Robust and wearless

- Max. 4000 pulses per revolution

- Output stage TTL with regulator UB 9...26 VDC

The HG16 from Baumer is a bearingless incremental encoder

- Operating temperature: -30...+100 °C

- Vibration: 10 g, 10-2000 Hz

- Impact: 100 g, 6 ms

- Weight: approx. 2.4 kg

- Connections: Terminal box or M23 flange connector, 12-pin

The Baumer HG18 is a bearingless incremental encoder

- Operating temperature: -30...+70 °C

- Vibration resistance: IEC 60068-2-6 (10 g, 10-2000 Hz)

- Impact resistance: IEC 60068-2-27 (100 g, 6 ms)

- Weight: approx. 4.2 kg

- Connection: Terminal box or M23 flange connector, 12-pin.

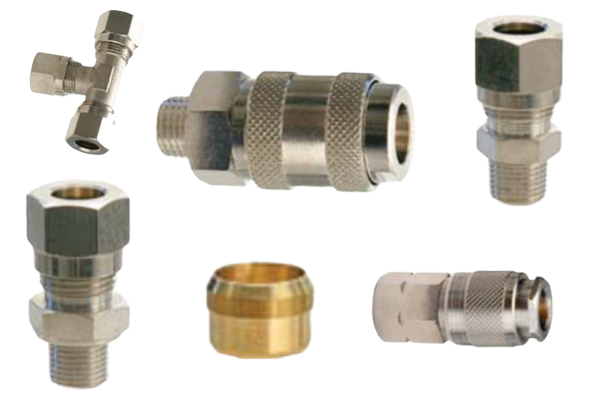

Push-on Fittings

Festo HGL

| Valve function | Piloted non-return function |

| Pneumatic connection, port 1 | G1/2 |

| Pneumatic connection, port 2 | G1/2 |

| Operating pressure | 0.5 bar - 10 bar |

Olive Compression Fittings

- 1-channel isolated barrier

- 24 V DC supply (bus powered)

- Input for 2-wire SMART transmitters and current sources

- Signal splitter (1 input and 2 outputs)

- Dual output 0/4 mA ... 20 mA or 0/1 V ... 5 V

- Up to SIL 2 acc. to IEC 61508

- 1-channel isolated barrier

- 24 V DC supply (bus powered)

- Input for 2-wire SMART transmitters and current sources

- Signal splitter (1 input and 2 outputs)

- Dual output 0/4 mA ... 20 mA or 0/1 V ... 5 V

- Up to SIL 3 acc. to IEC 61508

- 1-channel isolated barrier

- 24 V DC supply (bus powered)

- Dry contact or NAMUR input

- Usable as signal splitter (1 input and 2 outputs)

- 2 passive transistor outputs

- 1-channel isolated barrier

- 24 V DC supply (bus or loop powered)

- Output 45 mA at 12 V DC

- Line fault transparency (LFT)

- Test pulse immunity

- Up to SIL 3 acc. to IEC/EN 61508

- System board for HIMA, HIMax

- For 16-channel card X-AO 1601 (AO, single mode)

- 16-channel card X-AO 1601 (AO, redundant mode on request)

- For 16 modules

- Recommended module: HiC2031 (AO)

- 24 V DC supply

- Hazardous area: spring terminals, blue

- Safe area: HIMA system connector, 96-pin

- System board for Triconex (approval TAN48)

- For 32-channel AI cards 3700A, and 3721

- For 16 modules

- Recommended module: HiC2025 (AI)

- 24 V DC supply

- Hazardous area: pluggable screw terminals, blue

- Safe area: ELCO socket, 56-pin