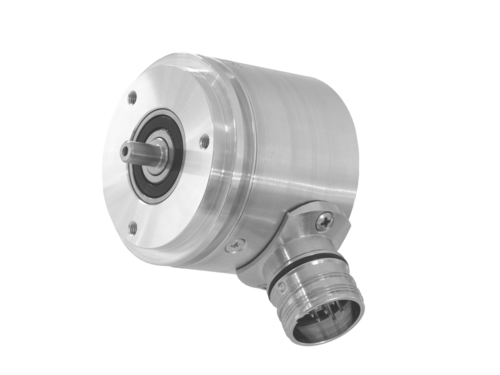

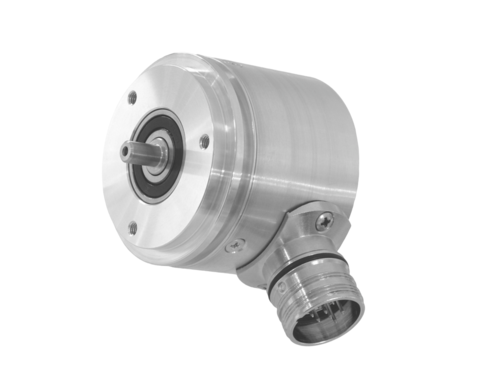

Baumer Absolute encoder

Baumer BMMH 58 analog - MAGRES absolute encoder

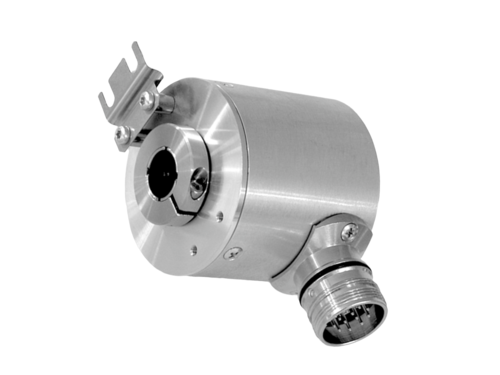

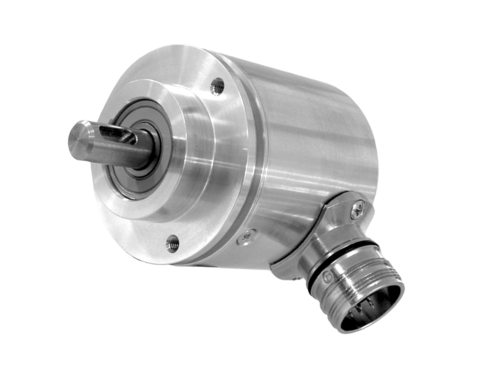

Magnetic single- or multiturn encoders

single or multiturn and bus cover encoders

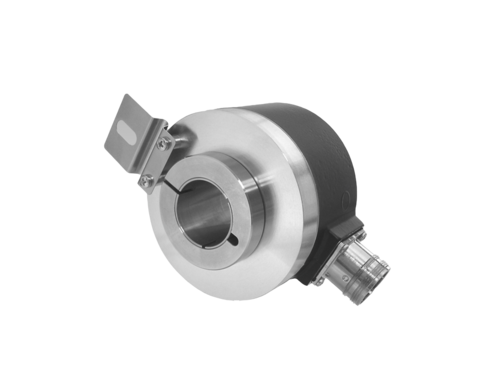

Magnetic multiturn encoder

Multi-turn absolute encoder

amg 11

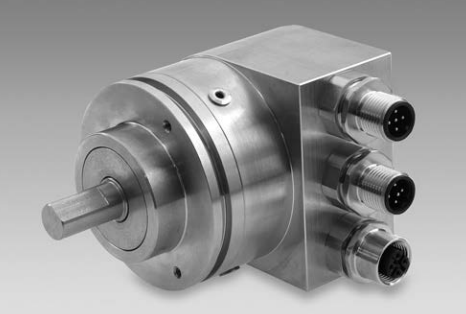

- Multiturn SSI / Profibus / CANopen® / DeviceNet / PROFINET

- Optical sensing method

- Singleturn 13 bit, multiturn 12 bit / 16 bit

- EURO flange B10 / solid shaft ø11 mm

- Multiturn sensing with microGen technologie, without gear or battery

- Available with redundant absolute signals

AMG 11 + FSL

- Code: Gray (SSI Version)

- Code Sequence: CW by default

- Inputs: SSI clock (SSI version)

amg 71

- Measurement method: Optical

- Code: Gray

- Code sequence: CW

- Inputs: SSI clock

AMG 73 S W29 S2048

- Interface: SSI (Synchronous Serial Interface)

- Output signal: Parallel, SSI

- Maximum refresh rate: 10 kHz

- Moment of inertia: 6.2 x 10^-6 kg·m²

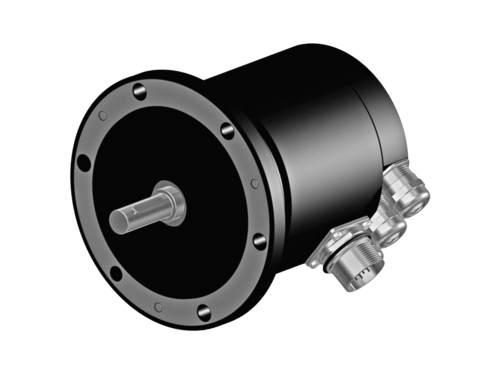

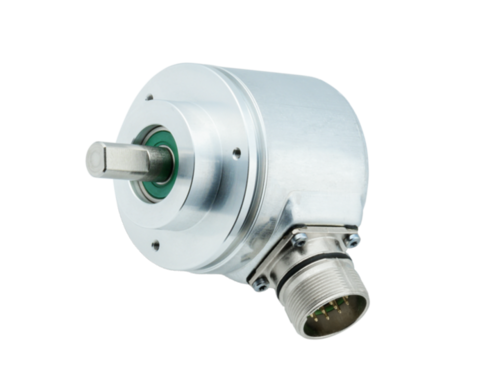

AMG 81

- Optical sensing method

- Multiturn/SSI/Profibus/CANopen®

- Singleturn 13 bit, multiturn 12 bit / 16 bit

- EURO flange B10 / solid shaft ø11 mm

ATD 07S A 4

- Measurement method: Magnetic

- Resolution: 12 bits (single revolution)

- Blind hollow shaft diameter: 4 mm

- Output signals: Gray code

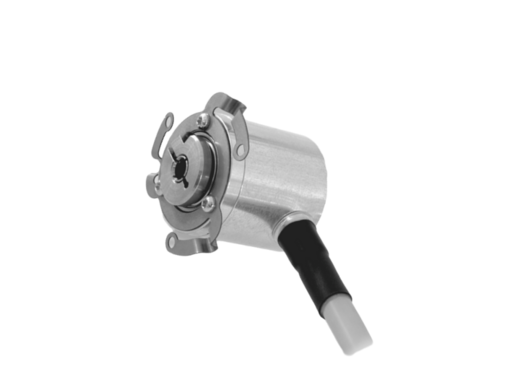

ATD 2A B14 Y 1

- Solid shaft ø6 mm with synchro flange

- Analog signals

- 14 bit singleturn

- Factory-set adjustable angle (0° - 360°)

- Centering alignment ø50 mm, mounting screw hole circle ø68 mm

ATD 2B A 4 Y26 absolute encoder

ATD 2B B14 Y22 absolute encoder

ATD 2S A 4 Y 7

- Through hollow shaft ø10 to ø14 mm

- Encoder multiturn / SSI

- Optical sensing singleturn, magnetical sensing multiturn

- Resolution: max. multiturn 24 bit

- Self-diagnostic

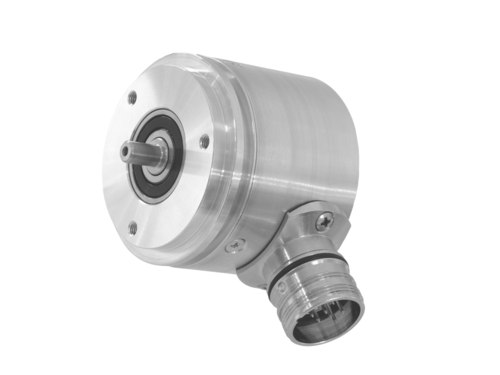

ATD 2S B14 Y21 absolute encoder

- Single-turn / SSI encoder

- Optical sensing

- 13-bit resolution (ST)

- Centering ø36 mm, mounting screw hole ø48 mm

- Flanged radial connector

ATD 2S B14 Y23

- Solid shaft ø10 mm with clamping flange

- Encoder single- or multiturn / SSI

- Optical sensing singleturn, magnetical sensing multiturn

- Resolution: max. singleturn 14 bit, multiturn 24 bit

- Centering alignment ø36 mm, mounting screw hole circle ø48 mm

- Self-diagnostic

ATD 2S B14 Y24

- Solid shaft ø10 mm with clamping flange

- Encoder single- or multiturn / SSI + resolver

- Two-in-one measuring system

- Magnetic sensing method

- Resolution: singleturn 12 bit, multiturn 12 bit

- Self-diagnostic

ATD 4B A 4 Y11 absolute encoder

ATD 4S A 4 Y10 absolute encoder

- Shaft type: Thru shaft with a diameter of 20 to 27 mm

- Resolution: Single-turn - up to 15 bits, multi-turn - up to 24 bits

- Reading method: Optical (single-turn), magnetic (multi-turn)

- Interface: SSI (Serial Synchronous Interface)

Baumer BFF CANopen®

- Blind or through hollow shaft ø12 mm

- Encoder singleturn / CANopen®

- Optical sensing method

- Resolution: 13 bit

- Integrated fieldbus interface

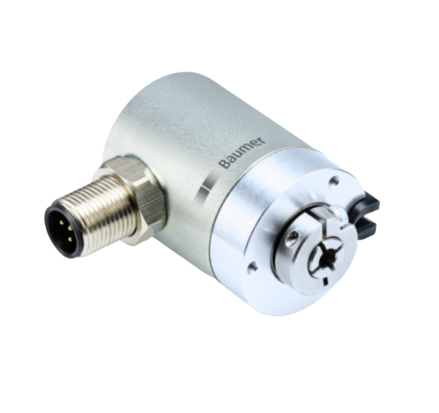

BMMH 30 SSI - MAGRES absolute encoder

Baumer BMMH 42 CANopen® - MAGRES is a mini absolute encoder

BMMH 42 DeviceNet - MAGRES

Baumer BMMH 42 SSI - MAGRES absolute encoder

BMMH 58 CANopen® - MAGRES

- Encoder multiturn / bus cover

- Robust magnetic sensing

- Resolution: singleturn 12 bit, multiturn 18 bit

- Modular fieldbus interfaces

- CANopen®/DeviceNet/EtherCAT/EtherNet-IP/SAEJ1939/PROFINET/POWERLINK/Profibus

- Resolution and zero point programmable

- High resistance to shock and vibrations

- Operating temperature -40...+85 °C

| Voltage supply | 5 VDC ±10 % 10...30 VDC |

| Consumption typ. | 100 mA (5 VDC, w/o load) 50 mA (24 VDC, w/o load) |

| Sensing method | Magnetic |

| Operating temperature | -20...+85 °C |

| Inputs | SSI clock Zero setting input |

BMMK 42 CANopen® - MAGRES

BMMK 58 CANopen® - MAGRES

- Magnetic sensor bore max. ø12 mm

- Encoder kit single- or multiturn / bus cover

- Magnetic sensing method

- Resolution: singleturn 12 bit, multiturn 18 bit

Baumer BMMK 58 SSI - MAGRES is a mini absolute encoder

Baumer absolute encoders are rotary encoders that have a unique code output for each shaft position. The shaft position is monitored even when there is no supply voltage, and the position signal is transmitted as a digital code. The ability to monitor the shaft position even when the power supply is switched off is the main reason why Baumer Hubner GmbH absolute encoders are used in applications with high demands on accuracy and safety.

Absolute encoders encoding a position within one revolution are called single-turn encoders, while encoders with a revolution counter are called multi-turn encoders. The most common output types are parallel code, SSI, CAN-open, and Profibus DP interfaces. A distinction is made between magnetic and optical encoders according to their operating principle. The latter, like incremental encoders, detect the rotation of an optical disc, while magnetic encoders detect the passage of magnetic poles past a sensor element. A built-in rechargeable battery allows the encoder to track shaft position when the power is off, but the position code is only transmitted when the power is on.

Advantages of the Baumer absolute encoder

Baumer Hubner GmbH offers single and multi-turn absolute encoders. Baumer Hubner GmbH encoders can measure up to 8192 (13 bit) shaft positions within a single revolution, 4096 (12bit), or 65536 (16 bit) shaft revolutions. An ultra-precise single-turn encoder model has also been developed that can record up to 4194304 (22 bit) shaft positions within a single revolution. Baumer absolute encoder output and programming is via an SSI interface and can also be connected to external units via Profibus, Device Net, or CANopen. Combination units with absolute and incremental parts are available.

Advantages of absolute encoders:

- No wear parts (except AMG 10 / AMG 81 models), ball bearing life is about 109 revolutions.

- Continuous high-speed operation is possible, even during start-up.

- Availability of models with solid shaft and hollow shaft.

- Robust construction with high impact resistance.

- Easy-to-understand Baumer absolute encoder manual.

- Immune to electromagnetic interference.

- Optional: redundant versions.

Features of Baumer technology

The Baumer Group's customers range from small, highly specialized factories and engineering plants to large industrial plants and international groups of companies. Because of their high shock and vibration resistance, explosion safety, and wide range of operating temperatures Baumer Group's devices are successfully used in the paper, steel, mining, food, semiconductor industries, in the print shop, metallurgy, rolling equipment, cooling units, portal cranes and other lifting equipment, packaging and textile equipment, automation of warehouses and terminals, explosive production, medical laboratory equipment, etc.

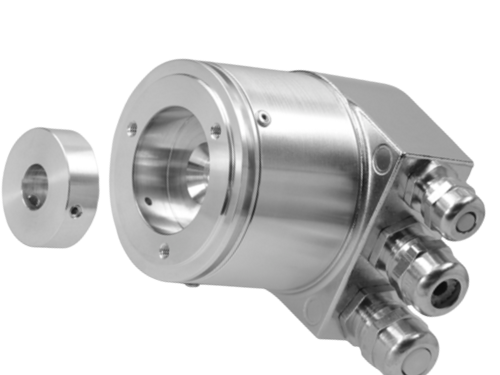

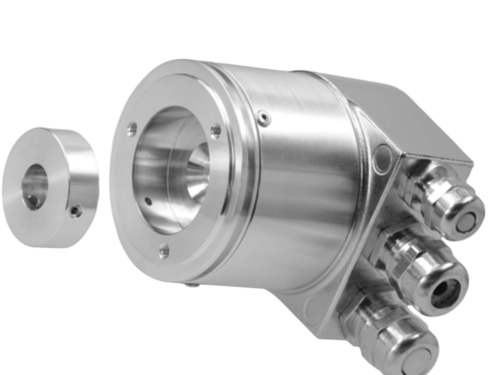

Robust construction

The one-piece enclosure made of aluminum or stainless steel is highly impacted resistant. Special surface protection for particularly aggressive environments. Protection rating up to IP 69K. Extremely wide operating temperature range. Electrical connection for every application: terminal boxes, internal connection clamps, metal plugs, or cables without plugs.

Optimized bearings

Reinforced ball bearings High radial and axial shaft load limit provided by mounting bearings on both ends of the shaft, if structurally possible. This provides additional advantages: there is a possibility to create a complete combination of several twisted together encoders, speed relays, etc. In addition, the other end of the shaft can be used to mount additional external devices. One side of the encoder with a large diameter hollow shaft bearing, installed if the advantages of a single-sided bearing arrangement outweigh the advantages. Versions without bearings are available for specific applications.

Protection against stray currents

For hollow shaft encoders, parasitic currents generated by the motor and flowing from the axis through the encoder body to the ground can be prevented by using insulating ceramic ball bearings and the parasitic current must be removed from the axis by means of an earthing contact ring. For encoders with a solid protruding shaft, a dielectric spring coupling with an insulated hub is used to protect against the parasitic pulsating current.

More detailed information you can see here:![]()