Bosch Rexroth Hydraulics

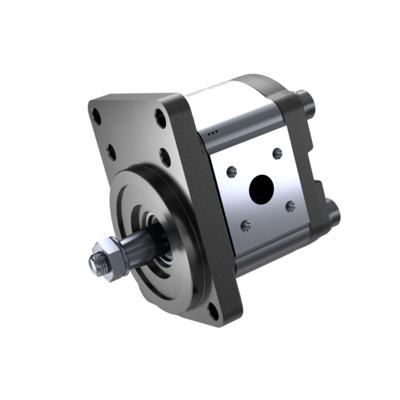

bosch 0510525009

- Noise level: 68 dB(A) at 3000 rpm and 10 bar

- Viscosity of the working fluid: From 10 to 300 cSt

bosch 0510625315

- Filter: Built-in filter with mesh element

- Protection level: IP67

- Working fluid: Hydraulic oil

517625006

- Noise level: 70 dB (A) at 3000 rpm

- Temperature of working fluid: from -40°C to +100°C

- Viscosity of the working fluid: from 14 to 320 cSt

- Body material: aluminum

- Shaft material: steel

538103012

- Battery type: Lead-acid

- Discharge current: Up to 100 A

- Service life: Up to 5 years

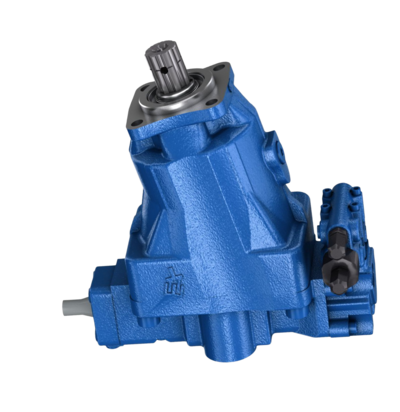

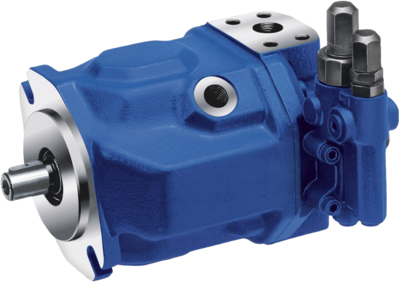

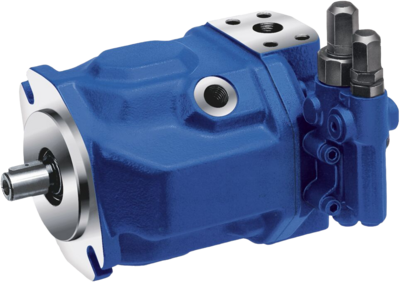

rexroth a18vo

- Noise level: < 70 dB(A)

- Temperature of working fluid: -40°C to +100°C

- Filtration: 10 μm

- Viscosity of the working fluid: 32 - 100 cSt

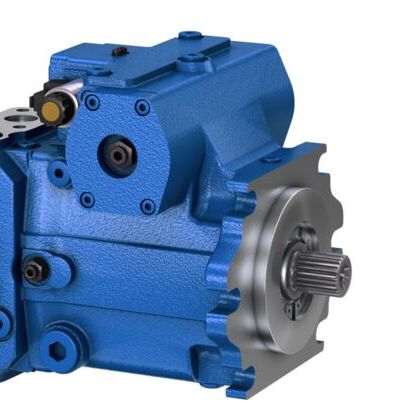

rexroth a22vg

- Temperature range: From -40°C to +80°C

- Noise level: 70 dB(A) at maximum pressure and rotation speed

- Body: aluminum

- Shaft: alloy steel

- Pistons: steel

- Sealing: nitrile butadiene rubber (NBR) or ethylene propylene rubber (EPDM)

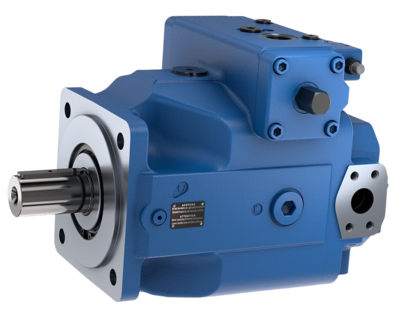

a4vso 250 rexroth

- Noise level: 70 dB (A) at maximum speed and pressure

- Fluid: HLP mineral oil or non-flammable HF fluid

- Filtration: a filter with a filtration fineness of 10 microns is recommended

- Oil viscosity: 32-68 cSt at operating temperature

- Body: aluminum

- Plate: steel

- Pistons: steel

- Sealing: rubber or fluororubber

hcs02 1e w0012

- Rated voltage: 200 V - 500 V DC

- Operating voltage range: 150 V - 550 V DC

- Maximum current: 12 A

msm019b

- Operating voltage range: 48-84 V

- Maximum current: 2.2 A

- Nominal frequency: 50-60 Hz

- Power factor: 0.9

- Insulation class: F

- Type of cooling: Forced air

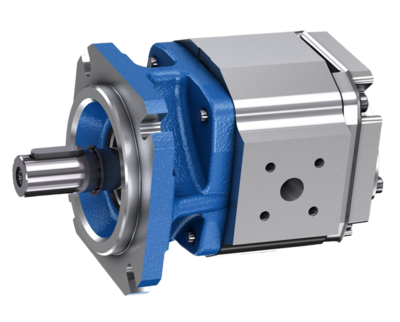

rexroth pgf2

- Maximum rotation speed: 3600 rpm

- Minimum: 100 rpm

- Working Viscosity: 2 to 350 cSt

- Operating Temperature: from -20°C to +80°C

rexroth pv7 1x 06 10ra01ma0 10

- Noise level: 70 dB(A) at 1000 rpm and 10 bar (145 psi)

- Filtration: It is recommended to use a filter with a nominal bandwidth of 10 µm

- Temperature range: -20°C to +80°C (-4°F to +176°F)

Rexroth hydraulic pump

4 cmі/rev, Clockwise rotation, Conical 1:5, Rectangular flange Dia. 80 mm, Square flange to fitting ISO 8434-1

HYDRAULIC GEAR PUMP AZPF-12-004RCB20KB

5.5 cmі/rev, Clockwise rotation, Conical 1:5, Rectangular flange Dia. 80 mm, Rectangular flange to fitting ISO 8434-3

HYDRAULIC GEAR PUMP AZPF-11-005RCB20MB

Gear Pump External

8 cmі/rev, Clockwise rotation, Conical 1:5, Rectangular flange Dia. 80 mm, Rectangular flange to fitting ISO 8434-2

HYDRAULIC GEAR PUMP AZPF-11-008RCB20MB

11 cmі/rev, Clockwise rotation, Conical 1:5, Rectangular flange Dia. 80 mm, Rectangular flange to fitting ISO 8434-4

HYDRAULIC GEAR PUMP AZPF-11-011RCB20MB

Gear Hydraulic

"14 cmі/rev, clockwise rotation, Conical 1:5, Rectangular flange Ш 36.47 mm (M8), Square flange (Italian version)"

HYDRAULIC GEAR PUMP AZPF-12-014RHO30KB

"14 cmі/rev, clockwise rotation, Conical 1:5, Front bearing Ш 80 mm type 2, Square flange DIN 3901/3902"

HYDRAULIC GEAR PUMP AZPF-10-014RSG20MB

510566001 Hydraulic Gear

11 cmі/rev + 1 cmі/rev , Rectangular flange Ш 80 mm, clockwise rotation, Conical 1:5, Square flange DIN 3901/3902, Metric thread to DIN 3852T1, Standard

HYDRAULIC GEAR PUMP AZPFB-11-011/1.0RCB2002MB

16 cmі/rev, Clockwise rotation, Conical 1:5, Rectangular flange Dia. 80 mm, Square flange to fitting ISO 8434-1

HYDRAULIC GEAR PUMP AZPF-11-016RCB20MB

510625055 External Gear

19 cmі/rev , Clockwise rotation, Conical 1:5, SAE J744 82-2 (A) 2-bolt flange, Square flange to fitting ISO 8434-1

HYDRAULIC GEAR PUMP AZPF-11-019RCR20KB

22.5 cmі/rev, Counter clockwise rotation, Conical 1:5, 2-bolt mounting Dia. 50 mm (K H D), Square flange to fitting ISO 8434-1

HYDRAULIC GEAR PUMP AZPF-12-022LCP20KB-S0007

Rexroth Hydraulic Gear Pump

"56 cmі/rev, clockwise rotation, Splined shaft SAE J744 22-4 (13T 16/32DP), SAE J744 101-2 (B), Rectangular flange SAE metric thread"

HYDRAULIC GEAR PUMP AZPG-22-056RDC07MB

Bosch Hydraulic Gear Pump

"4 cmі/rev, clockwise rotation, Conical 1:5, Rectangular flange Ш 80 mm, Rectangular flange for fitting ISO8434-1"

HYDRAULIC GEAR PUMP AZPS-11-004RCB20MB

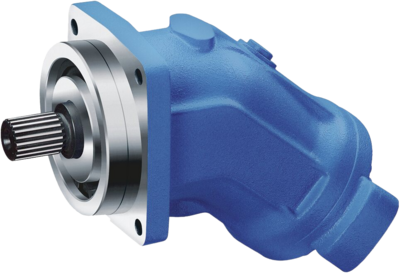

a10vno rexroth

- Liquid temperature: From -40°C to +100°C

- Liquid viscosity: 10-32 cSt at 40°C

- Liquid filtration: Purity class ISO 14/12

- Noise level: 70 dB(A) at maximum pressure and flow

a10vso 18 dfr1 31r vpa12n00

- Noise level: 70 dB (A) at 3000 rpm

- Body: aluminum

- Connection ports: SAE A

a10vso100 rexroth

- Noise level: 70 dB (A) at 3600 rpm

- Working fluid temperature: from -20°C to +80°C

- Viscosity of the working fluid: 10-32 cSt

- Control type: manual/electronic

- Non-return valve: optional

- Filter: optional

rexroth a10vso18

- Filtration: an external filter with a purity of 10 μm is recommended

- Noise level: < 70 dB(A) at 100 l/min and 350 bar

- Working fluid temperature: from -20°C to +80°C

- Ambient temperature: from -40°C to +80°C

rexroth a1vo

- Stroke volume: From 10 cm³/rev to 100 cm³/rev

- Number of groups: From 1 to 6

- Liquid temperature: From -40°C to +130°C

- Noise level: Up to 70 dB (A)

a2fm107

- Working fluid temperature: from -20°C to +80°C

- Viscosity of the working fluid: from 15 to 350 cSt

- Noise level: up to 70 dB(A)

- Protection class: IP65

- Certificates: CE, RoHS

a2fm32

- Power: up to 30 kW

- Working fluid temperature: From -20°C to +80°C

- Noise level: 70 dB (A) at 2500 rpm, 400 bar

Bosch Rexroth has earned its reputation as a leader in the hydraulic industry through decades of innovation, quality manufacturing, and commitment to customer satisfaction. As a division of the Bosch Group, Bosch Rexroth leverages the vast resources and expertise of its parent company while maintaining a specialized focus on industrial automation and hydraulic technology.

What sets Bosch Rexroth apart is its comprehensive approach to hydraulics. The company offers a diverse range of products and solutions, from hydraulic pumps and motors to valves, cylinders, and power units. This breadth of offerings allows customers to find everything they need for their hydraulic systems in one place, simplifying the procurement process and ensuring compatibility among components.

Innovation is key aspect of Bosch Rexroth's leadership. The company invests heavily in research and development to stay at the forefront of hydraulic technology. This focus on innovation has led to advanced control systems, energy-efficient products, and customized solutions tailored to specific customer needs. By continually pushing the boundaries of what hydraulics can do, Bosch Rexroth ensures its customers have access to the latest advancements in the field.

Bosch Rexroth Hydraulic Products

Bosch Rexroth offers a comprehensive range of hydraulic products, each designed to meet the varied demands of industrial automation and manufacturing.

Bosch Rexroth compact hydraulics is a range of miniature hydraulic components designed for applications in tight spaces. Rexroth compact hydraulics combine high performance with a compact size, making them the ideal choice for a wide range of industries where miniaturization and precision are important.

Accumulators

Bosch Rexroth batteries are used to store energy in hydraulic and pneumatic systems. Their batteries are known for their high quality, reliability and efficiency.

Advantages of using Bosch Rexroth batteries

- Energy storage: Batteries can store the energy generated by pumps for use later when needed. This can help to reduce peak load on the system and save energy.

- Pulsation damping: Batteries can help dampen pressure fluctuations in the system, which can improve performance and extend component life.

- Leakage compensation: Batteries can be used to compensate for leaks in the system, which can help maintain pressure.

Types of Bosch Rexroth accumulators

- Hydraulic accumulators: These accumulators are used in hydraulic systems to store hydraulic energy. They come in a variety of types, including bubble, piston, and diaphragm type accumulators.

- Pneumatic accumulators: These accumulators are used in pneumatic systems to store compressed air. They come in a variety of types, including bubble, piston, and diaphragm batteries.

Cylinders

Bosch Rexroth cylinders are used for linear motion or rotation in hydraulic and pneumatic applications. Their cylinders are known for their robustness, reliability and precision.

Advantages of using Bosch Rexroth cylinders

- Wide range of sizes and strokes: Bosch rethrox offers a wide range of cylinder sizes and strokes to meet every need.

- High strength: Rexroth cylinders are made of high quality materials and can withstand high loads.

- Reliability: Cylinders are known for their reliability and long service life.

- Precision: Provide high positioning and speed accuracy.

Types of Bosch Rexroth cylinders

- Hydraulic cylinders: These cylinders are used in hydraulic systems to provide linear motion or rotation. They come in a variety of types, including piston, plunger, and rotary cylinders.

- Pneumatic cylinders: These cylinders are used in pneumatic systems to provide linear motion or rotation. They come in a variety of types, including piston, plunger, and rotary cylinders.

Electronics and control systems

Bosch Rexroth electronics and control systems are used to control the movement and operation of hydraulic and electric actuators. Their control systems are known for their flexibility, precision, and reliability.

Advantages of using Bosch Rexroth electronics and control systems

- Flexibility: Bosch Rexroth control systems can be easily customized to meet specific requirements.

- Precision: control systems provide high positioning and speed accuracy.

- Reliability: Bosch Rexroth control systems are known for their reliability and long service life.

- Ease of use: Rexroth control systems are easy to use and program.

Types of Bosch Rexroth electronics and control systems

- Motion control systems: These systems are used to control the motion of hydraulic and electric actuators. They include servo drives, motion controllers, and motion control software.

- Pressure control systems: These systems are used to control pressure in hydraulic systems. They include proportional valves, pressure regulators, and pressure transmitters.

- Software: Bosch Rexroth offers a wide range of software for the design, configuration and maintenance of its control systems.

Pumps

Rexroth hydraulic pump are used to generate hydraulic power or compressed air. They are known for their high performance, energy efficiency, and reliability.

Advantages of using Bosch Rexroth pumps

- High performance: Bosch Rexroth pumps can generate high power flow to power hydraulic and pneumatic systems.

- Energy efficiency: pumps are designed to minimize energy loss and provide high efficiency.

- Reliability: pumps are known for their reliability and long service life.

- Quiet operation: Bosch Rexroth pumps are quiet, which contributes to a better working environment.

Types of pumps

- Hydraulic pumps: These pumps are used to generate hydraulic power in hydraulic systems. They come in various types, including gear pumps, vane pumps, piston pumps, and axial piston pumps.

- Pneumatic pumps: These pumps are used to generate compressed air in pneumatic systems. They come in a variety of types, including vane, reciprocating, and scroll compressors.

In addition to the products listed above, Rexroth offers a wide range of other components for hydraulic and pneumatic systems, including:

- Actuators: Rexroth drives convert electrical energy into mechanical energy to power machines and equipment.

- Heat treatment systems: Bosch Rexroth heat treatment systems are used to cool or heat hydraulic oil.

- Filters: Filters clean hydraulic oil from contaminants to help extend the life of system components.

- Valves: Rexroth offers a wide range of valves to control fluid flow and pressure in hydraulic systems.

- Controls: Bosch Rexroth offers joysticks, pedals, and other

Choosing Bosch Rexroth for Your Hydraulic Needs

When selecting hydraulic solutions, customization and flexibility are crucial factors that can significantly impact your operations. Bosch Rexroth understands that each industry and application has unique requirements, which is why they offer a high degree of customization and flexibility in their hydraulic products.

Customization for Specific Applications

Rexroth provides tailored hydraulic solutions to meet the specific demands of various industries. Whether you're in manufacturing, construction, renewable energy, or aerospace, the ability to customize hydraulic components can make a significant difference in performance and efficiency. Bosch Rexroth's approach to customization allows clients to define their exact requirements, ensuring that the hydraulic system is perfectly suited to their operations.

Flexible Hydraulic Components

Rexroth offers a wide range of hydraulic components, from pumps and valves to cylinders and accumulators. This broad selection allows for flexibility in design and implementation. Customers can choose from various configurations and options, enabling them to create a hydraulic system that aligns with their specific needs. The flexibility to select components based on factors like power output, pressure range, and operational environment provides a high level of adaptability.

Modular Design for Easy Integration

Another aspect of flexibility is the modular design of bosch rexroth hydraulic. The modular approach allows components to be easily integrated into existing systems or reconfigured as needed. This design philosophy simplifies maintenance and reduces downtime, as individual components can be replaced or upgraded without affecting the entire system. The modularity also facilitates scalability, allowing customers to expand their hydraulic systems as their operations grow.

Bespoke Solutions for Unique Challenges

Bosch Rexroth goes beyond standard customization by offering bespoke solutions for unique challenges. The company's engineering teams work closely with clients to understand their specific requirements and develop custom hydraulic systems that meet those needs. This collaborative approach ensures that customers receive a hydraulic solution that is both efficient and effective, regardless of the complexity of their application.

Versatility Across Industries

Rexroth's customization and flexibility make their hydraulic systems suitable for a wide range of industries. Whether it's a compact hydraulic solution for a robotic arm in a manufacturing plant or a high-pressure system for heavy machinery on a construction site, Bosch Rexroth has the expertise and product range to meet the challenge.This versatility allows customers to trust Bosch Rexroth for all their hydraulic needs, knowing they will receive a solution tailored to their specific industry.

Hydraulic systems are the backbone of many industrial applications, offering power, flexibility, and precision. If you're unsure about which hydraulic system is best for your application, or if you have questions about product specifications, Eltra Trade's experienced managers are always ready to assist.