Pepperl+Fuchs Explosion Protection

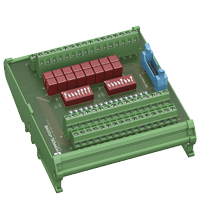

- Connection board for K-System HART Multiplexer

- 16-channel

- Interface for series connection or parallel connection

- Integrated, switchable 220 Omega- resistor

- 8-channel

- Inputs Ex ia

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Dry contact or NAMUR inputs

- Positive or negative logic selectable

- Simulation mode for service operations (forcing)

- Line fault detection (LFD)

- Permanently self-monitoring

- Module can be exchanged under voltage

Segment Protector

- High reliability

- Wide range of security features

- Easy installation and configuration

Pepperl+Fuchs Multi-input/output (MIO)

- 12 discrete inputs and outputs

- Aluminum housing with IP66 protection

- Support for FOUNDATION Fieldbus H1

Converts 10, 100, and 1000BASE-T to 1000BASE-SX

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

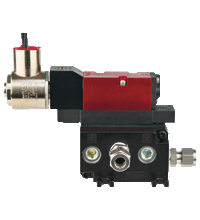

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

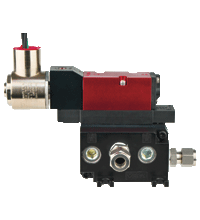

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Class I, II/Div. 2 for hazardous locations

- Certified for UL CSA

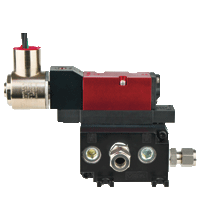

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Suitable for Zone 2&22

- ATEX & IECEX certifications

- Manifold combines the solenoid valve for purging and needle valve for pressurization in one housing

- Suitable for steel or plastic tubing

- Mounting hardware, pneumatic fittings and tubing included

- Intrinsically Safe, 4 ... 20 mA proportional valve

- Pneumatic connections 10 mm compression ferrule tube fittings

- ATEX certification

- Maximum flow of around 8 scfm

- Closed loop flow rate control for precise dilution applications

- Must be used in conjunction with an EPV-7500-* vent

- Low cost, compact design, easy to use

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

- Must be used in conjunction with an EPV-7500-* vent

- External mount, square box

- Universal power: AC or DC

- Touch screen display with LEDs for easy visual indication

- Easy setup with pre-set purge programs for your application

- Automatic pressure compensation with digital manifold

- Rugged, corrosion-resistant housing

- Global third-party approvals for Class I, II, Div. 2 and Zone 2/22

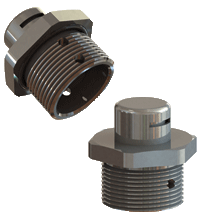

- Manual valve, no electrical power requirement

- Purge and pressurization valving in one device

- Ex e and Ex tb certified

- Suitable for operation in Zone 1, Zone 2, Zone 21 and Zone 22

- Stainless Steel

- Thread M20

- Seal silicone

- Packaging unit: 35 pieces, with accessories

Adjustable output 15 ... 30 V/max.1 A

- Industrial-grade box thin client for 24/7 operation

- Long-term support with product availability for more than 5 years

- Supports modern Ultra HD (4K) setups with 60 Hz

- Compact footprint and wide operating temperature range

(-20 ... 60 В°C) for high installation flexibility

- Allows direct connection from a VisuNet Remote Monitor (with RM Shell 4.1 or newer) to a host system

- Supports concurrent remote and local access to an Operator Workstation

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

- Galvanic Isolation I.S. to non-I.S. Port

- 10/100 MBit/s according to IEEE 802.3/.3u

- Installation in Zone 2, Ethernet in Zone 1 or Zone 0

- Standard Ethernet patch or crossover cable

- DIN-Rail mounted and OEM Version

- Replaceable SIM

- Global certificates - a common hardware platform

- Android 8.1 operating system

- Wireless connections such as WWAN, 4G LTE, WLAN, etc.

- Android Enterprise Recommended verified device

- GPS

- NFC technology for wireless applications

- Service contract

- Special buttons for push-to-talk (PTT) applications

- Special buttons for lone worker protection (LWP) applications

- Latest available Android version for this device

Segment Protector

- 1-channel

- Fully compatible replacement for FB3203B

- Input Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2- or 3-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- HART communication also for separately powered devices

- Simulation mode for service operations (forcing)

- Line fault detection (LFD) and Live Zero monitoring

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Inputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD)

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Module can be exchanged under voltage (hot swap)

- Installation in suitable enclosures in Zone 1

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- 4-channel

- Outputs Ex ia

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- Analog output module for 0/4 mA ... 20 mA

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Output with bus-independent safety shutdown

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via PROFIBUS DP

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS TCP

- Installation in suitable enclosures in Zone 1

- Module can be exchanged under voltage (hot swap)

- HART communication via MODBUS TCP

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

Expanding the scope of electrical devices in explosive areas requires high professionalism in the approach to the selection of elements of electrical systems and explosion-proof equipment. Today we will look at the Pepperl+Fuchs explosion protection solution.

What is an Explosion Protection System?

Explosion protection equipment is designed to suppress, isolate and remove combustible dust or vapors. These systems have many applications in the manufacturing industry, including energy, food and grain, plastics, pharmaceuticals, wood and paper, paints, and pigments.

For a product or electrical equipment to be classified as "explosion-proof", this means that the enclosure of the product must be capable of withstanding internally:

- Any internal explosion.

- Any sparks that form internally prevent the ignition of vapors, gases, fibers, or dust in the environment from these sparks.

This also means that we should not be mistaken that explosion-proof electrical products are capable of withstanding any external explosion occurring outside of the enclosure, but rather the ability of the enclosure to prevent any internal explosion or sparks from entering the enclosure. environment and cause a larger explosion. The term "explosion-proof" is also interchangeable with "fire-resistant".

Thus, the use of explosion-proof electrical products will bring you the following benefits:

- Safety. No employee wants to work in an unsafe environment or expose themselves to unnecessary risk in a dangerous environment. This will allow your employee to focus on their job and improve productivity and morale. Your employees will feel at ease knowing they work for an organization that values its safety by using explosion-proof products.

- Economic benefits. By using certified explosion-proof products, you will minimize damage to your plant by containing any explosion within the enclosure itself and not in surrounding areas. Another important fact is that any reduced external explosion will minimize any risk to your personnel and greatly reduce the likelihood of costs associated with medical claims or personnel litigation against your company for any workplace accidents.

What are the Methods of Explosion Protection?

There are various types of equipment that can be used in these hazardous areas to eliminate or greatly reduce the chance of an explosion. This equipment must be designed and built according to specific design parameters known as protection concepts. Essentially, these concepts fall under four main methods. These methods are detailed below along with a brief description of some of the concepts:

- Ex i intrinsically safe. Ex i is an explosion protection concept in which the electrical energy inside the equipment is limited to a level below that which can cause ignition or limit the heating of the surface of equipment in an explosive area.

- Ex d fireproof. Equipment capable of causing an explosion is enclosed in a sheath capable of withstanding the force of an explosion and preventing transmission to an external hazardous atmosphere. The Ex d explosion-proof method also prevents hazardous atmospheres from entering the enclosure and contacting the equipment.

- Ex m encapsulation. Ex m is an explosion protection concept in which equipment that has the potential to cause ignition is encapsulated in a compound or resin to prevent contact with an explosive atmosphere. The concept also limits the surface temperature of the equipment under normal operating conditions.

- Ex e increased safety. Ex e is an explosion protection concept applied to an installation to provide increased safety against the possibility of excessive temperatures and sparks from electrical equipment in hazardous areas. Equipment that normally generates sparks must not be used under this protection method.

- Ex p pressurized. One process ensures that the pressure inside the Ex p enclosure is sufficient to prevent the ingress of flammable gases, vapors, dust, or fibers and prevent possible ignition.

- Ex q powder filling. All equipment that can cause an arc discharge is enclosed in a case filled with particles of quartz or glass powder. Powder filling prevents fire.

- Ex n intrinsically safe. A type of protection in which precautions are taken so that hazardous area electrical equipment in which an arc may occur cannot ignite the surrounding explosive atmosphere.

- Ex s special. This explosion protection method, as its name suggests, has no special parameters or design rules. In essence, it is any method of explosion protection that can provide a given level of safety that guarantees the absence of ignition. As such, it does not fall under any particular protection method, and may in fact be a combination of more than one.

Buy Pepperl+Fuchs Explosion Protection

If you are interested in buying explosion protection equipment from Pepperl+Fuchs then Eltra Trade is the best place to do it. We have a complete list of products from the most famous suppliers in the world. Our professional managers will help you navigate the current cost of explosion protection equipment and help you find the solutions you need. If you have any questions, please contact us, and we will be happy to answer them.