Pepperl+Fuchs Explosion Protection

Choose a subcategory:

Show all categories

- Standard enclosure for FB-System

- Max. 5 slots for I/O modules

- For FOUNDATION Fieldbus H1

- Impact resistance enclosure, IP66/NEMA 4X

- Packaged certified solution

- Installation in Zone 1

- 8 segments, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 4 segments, redundant, individual modules per segment

- Supports all PLC and PCS hosts

- High-power trunk: Live work on devices in any hazardous area

- Features for best signal quality, low heat dissipation

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Supports Ex ic/nL voltage limitation

- Installation in Zone 2/Div. 2

- 8 segments, redundant, individual modules per segment

- Customized for Invensys, FBM228

- High-power trunk: Live work on devices in any hazardous area

- Best quality, smallest size and lowest heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance for high reliability

- Dual, redundant bulk power connections

- Comprehensive diagnostics for the fieldbus physical layer

- Handheld with display and integrated expert system

- Fieldbus interface Ex ia, FISCO, Entity, and DART

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Multi-language support

- Operation in Zone 1/Class I, Div. 1

- Choice of power options for different operating modes

- PC software for enhanced interface and data backup

- Comprehensive diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Automatic setup of diagnostic system

- Full software integration into PCS and PAM possible

- Diagnostics for fieldbus physical layer and power supply

- Plug-in Module for the FieldConnex Power Hub

- Plug and play - no engineering required

- For online monitoring

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Alarm limits configurable via DIP switches

- Fault indication transmission by voltage free contact

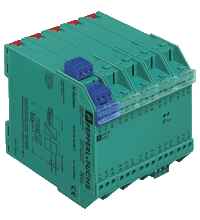

- Output: 21 ... 23 V/500 mA

- Voltage limitation for Entity ic and Ex nL

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

- Output: 28 ... 30 V/500 mA

- High-power trunk for high device count and long cable lengths

- With galvanic isolation

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- High efficiency, low heat dissipation for high packing density

- Hot swappable in redundant configuration

- Module exchange without tools during operation

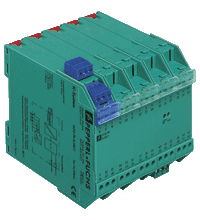

- PROFIBUS DP V1 / For 4 segments PA

- Couples PROFIBUS PA devices transparently to PROFIBUS DP

- Optional redundant configuration

- Installation in Zone 2/Class I, Div. 2

- Up to 12 Mbit/s, auto adapting

- For redundant and non-redundant masters

- Supports Flying Redundancy (FR)

- Cyclic/acyclic data exchange

- Gateway PROFINET RT to 4 x PROFIBUS PA segments

- Up to 32 devices per PROFIBUS PA segment

- Installation in Zone 2/Class I, Div. 2

- Ring and system redundancy

- Integrated webserver for diagnostics

- 32-channel

- 24 V DC supply

- HART field device input (revision 5 to 7)

- RS-485 interface

- Up to SIL 3 acc. to IEC 61508

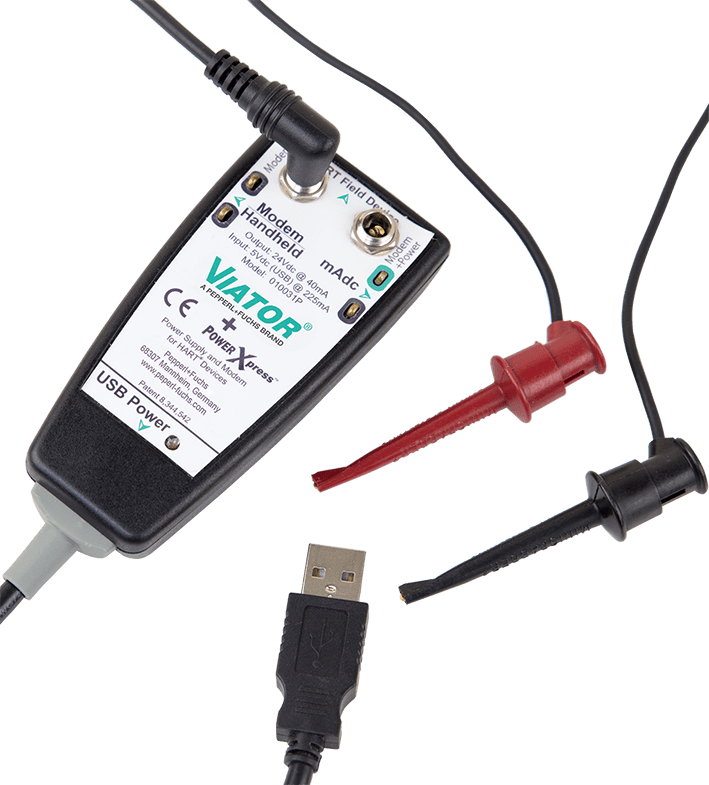

- Interface for wireless communication between PC host and any HART field device

- Registered with HART Communication Foundation

- ATEX and IECEx approval

- UL listed for North America

- Powerful, high-speed Bluetooth with 100 m open-air range

- Adaptive frequency hopping to reduce radio-frequency interference

- HARTCommDTM software supports use with FDT Frame applications

- Compatible with 32- and 64-bit Windows?® 7, 8, XP, 10, or Vista

- HART compliant for communication with any HART field device and error-free slave testing

- Draws power from USB port, needs no external supply to power modem

- Compact, rugged polycarbonate housing for industrial-grade reliability

- Quickly power and communicate with HART field devices

- Powers all 2-wire HART devices, independent of supplier

- Draws power from USB port, needs no external supply to power modem

- Compact, rugged polycarbonate housing for industrial-grade reliability

- Integrated connector cable terminates in 2 test clips and 1 USB connector cable

- Selectable powered-modem or modem-only mode

- Compatible with 32- and 64-bit Windows?® 7, 8, XP, 10, or Vista

HART Connection Cable with Connectors

- Output: 25 ... 27 V/360 mA

- For most fieldbus applications

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1

- Fixed, high-availability terminator

- No spacing required between modules

- Output: 24 ... 26 V/400 mA

- For extension of fieldbus segments

- High-power trunk for high device count and long cable lengths

- Installation in Zone 2/Class I, Div. 2

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Fixed, high-availability terminator

- High efficiency, low heat dissipation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to Entity

- 70 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

- Power supply of fieldbus segments according to IEC 61158-2

- Signal repeater for fieldbus topologies in accordance to FISCO

- 100 mA supply of the field side

- Improves the fieldbus signal

- Extension of the transmission distance by means of opening a new fieldbus segment

- Integrated bus terminations

- Removable terminals and Power Rail connection for simple installation

- Supply via Power Rail

- Comprehensive diagnostics for the fieldbus physical layer

- Module and motherboard for retrofit of any installation

- Precise measurements through passive circuits

- For commissioning, online monitoring and troubleshooting

- For FOUNDATION Fieldbus H1 and PROFIBUS PA

- Installation in Zone 2/Class I, Div. 2

- System state and fault indication via LEDs

- Display of data in the safety of the control room

- Full software integration into PCS and PAM possible

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Common alarm handling

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

- System integration kit for Advanced Diagnostics

- PCS integration via Diagnostic Manager or device DTM

- Simple automatic setup of Advanced Diagnostics

- Alarm handling and integrated I/O for cabinet monitoring/control

- For FOUNDATION Fieldbus and PROFIBUS PA

- Installation in Zone 2

Complete hardware for connection of FOUNDATION Fieldbus H1 field devices to the host system of your choice

Complete hardware for connection of PROFIBUS PA field devices to a DP-Master

- 4-channel

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Installation in Zone 2 or safe area

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Installation in Zone 2 or safe area

- Supply circuit 21.5 V (4 mA)

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Inputs Ex ia

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- Input from active signals of 4-wire transmitters

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 4-channel

- Inputs Ex ia

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Power supply for 2-wire transmitters with 4 mA ... 20 mA

- Supply circuit 15 V (20 mA)

- HART communication via field bus or service bus

- Simulation mode for service operations (forcing)

- Line fault detection (LFD): one LED per channel

- Permanently self-monitoring

- Module can be exchanged under voltage

- 8-channel

- Outputs Ex ib

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Module can be exchanged under voltage

- Galvanic group isolation

- Line fault detection (LFD)

- Positive or negative logic selectable

- Simulation mode for service operations (forcing)

- Permanently self-monitoring

- Output with watchdog

- Output with bus-independent safety shutdown