Endress+Hauser error codes

25.07.2024

Headquartered in Reinach, Switzerland, Endress+Hauser operates in more than 120 countries, ensuring that they can deliver exceptional service and support to customers around the world. This global network is a testament to their ability to maintain a local presence while addressing global industrial needs.

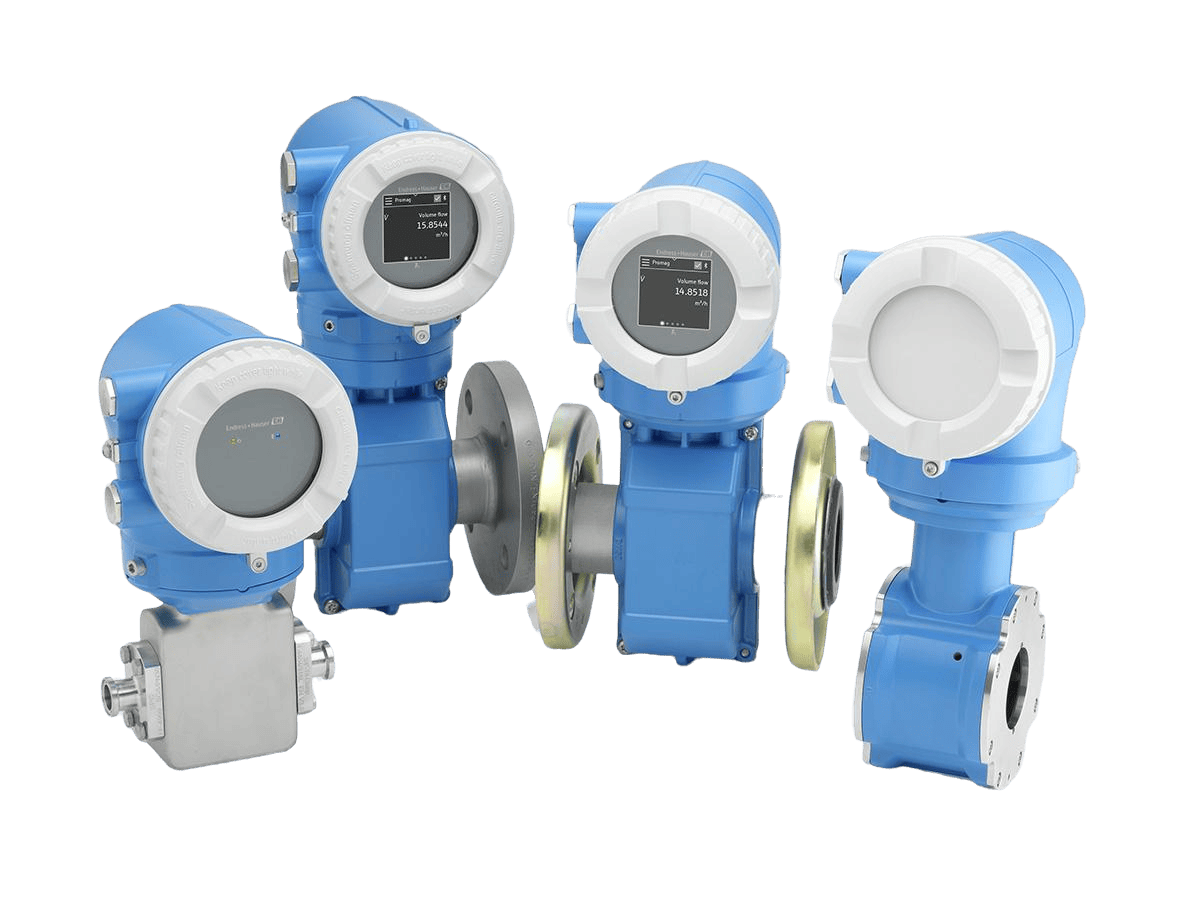

The endress hauser products range is comprehensive, encompassing sensors, e&h instruments, systems, and services designed for measuring level, flow, pressure, and temperature, as well as performing analytical and data acquisition tasks. These products find applications across a variety of industries, including chemical, food and beverage, oil and gas, water and wastewater, and life sciences. Each product is engineered with a focus on precision, reliability, and user-friendliness, ensuring optimal performance in diverse industrial processes.

Sustainability and corporate responsibility are integral to Endress+Hauser's ethos. The e&h company adheres to stringent environmental standards and actively works to minimize its ecological footprint. Moreover, Endress+Hauser is dedicated to social responsibility, supporting numerous community initiatives and educational programs. This holistic approach underscores their role as a responsible and forward-thinking corporate citizen.

Importance of Understanding Fault Codes

In the realm of industrial automation, understanding fault codes is pivotal for maintaining the seamless operation of equipment and systems. Fault codes serve as vital diagnostic tools that help identify and troubleshoot issues quickly and effectively. By gaining a thorough understanding of these codes, operators can ensure the longevity and reliability of their Endress+Hauser devices. Here’s a closer look at why comprehending fault codes is so essential:

- Minimizing Downtime

Downtime is one of the most significant concerns in industrial operations, as it directly impacts productivity and profitability. When a fault occurs, the ability to swiftly identify and resolve the issue can drastically reduce the amount of time a system remains non-operational. Fault codes provide precise information about the nature and location of a problem, enabling quick and targeted troubleshooting.

- Enhancing Efficiency

Efficiency in industrial processes is crucial for maintaining competitive advantage and achieving operational goals. Fault codes play a significant role in enhancing efficiency by enabling proactive and informed decision-making.

Common e&h products error codes

Endress+Hauser uses a coding system to indicate malfunctions in its devices. These codes can help users quickly determine the cause of the problem and take appropriate action.

Below is a description of some common Endress+Hauser fault codes and where they may occur:

| Fault Code | Description | Possible Causes |

| C: Communication Error | Communication problem between the sensor and the instrument or between the instrument and the control system. | Cable, connector, communication board, software |

| E: Electrical Error | Power supply problem for the sensor or instrument. | Power source, cable, connector, power board |

| F: Sensor Error | The sensor detects a fault or is outside the permissible measuring range. | Sensor element, sensor electronics, sensor cable |

| S: Setup Error | The sensor or instrument is not configured correctly. | Sensor or instrument software, configuration parameters |

| U: Unknown Error | The cause of the error is undetermined. | Sensor or instrument software, hardware fault |

It is important to note that these are only some of the most common Endress+Hauser error codes.

Common problems encountered by users with Endress+Hauser products.

1. Inaccurate measurements

- Contamination of sensors: This can lead to incorrect readings of level, flow, pressure or other parameters.

- Incorrect calibration: Over time, the calibration of sensors can drift, resulting in inaccurate measurements.

- Defective sensors: Sometimes sensors can fail due to manufacturing defects or damage during operation.

2. Problems with electronics

- Voltage drops: Sudden voltage drops in the power supply network can damage the electronic components of the devices.

- Corrosion: Corrosion due to exposure to moisture or aggressive environments can damage electronic boards.

- Defective components: Sometimes electronic components can fail due to manufacturing defects or aging.

3. Mechanical problems

- Wear and tear: Moving parts in instruments can wear out over time, leading to inaccuracies or breakdowns.

- Damage: Mechanical damage to devices due to impacts, vibration or other factors can lead to breakdowns.

- Improper installation: Improper installation of appliances can lead to problems with their operation.

4. Other problems

- Software problems: Errors in the software of instruments can cause incorrect readings or incorrect operation.

- Incompatibility: Different Endress+Hauser devices may be incompatible with each other, which can lead to problems with their operation in the system.

- Human error: Improper operation or maintenance of devices can lead to their failure.

It is important to note that these are only some of the common faults with Endress+Hauser products. Specific problems faced by users may vary depending on the type of device, operating conditions, and other factors.

Best practices for avoiding malfunctions with Endress+Hauser products

To minimize the risk of malfunctions with Endress+Hauser products, we advise you to follow these recommendations.

1. Correct choice of device

- Choose the device that meets your specific needs and operating conditions.

- Pay attention to the measurement range, accuracy, case materials and other characteristics of the device.

- Consult with Endress+Hauser specialists to choose the optimal device for your application.

2. Correct installation

- Follow the installation instructions provided with the appliance.

- Install the device in a place that is free from vibrations, shocks and extreme temperatures.

- Provide free access to the device for its maintenance.

3. Regular maintenance

- Carry out regular maintenance of the device in accordance with the operating instructions.

- This may include calibration, cleaning, inspection and replacement of worn parts.

- Regular maintenance will help prevent malfunctions and extend the life of the device.

4. Use of original spare parts

- Use only original Endress+Hauser spare parts for repair and maintenance of the device.

- The use of non-original spare parts can lead to malfunctions and loss of warranty.

5. Staff training

- Train personnel to properly operate and maintain the device.

- This will help prevent mistakes that could lead to malfunctions.

6. Monitoring the operation of the device

- Regularly monitor the operation of the device for signs of malfunctions.

- This may include tracing readings, visual inspection and checking for errors.

- Timely detection of malfunctions will help prevent serious breakdowns.

7. Contacting the technical support service

- If you have problems with the device, please contact Endress+Hauser technical support.

- Support specialists will help you diagnose the problem and find a solution.

By following these recommendations, you can significantly reduce the risk of malfunctions with Endress+Hauser products and extend their service life.

Use of Endress+Hauser diagnostic tools

Endress+Hauser offers a wide range of diagnostic tools to help you identify and troubleshoot your appliances. These tools may include:

- PC Software: This software can be used to connect to the instrument and read its data. The data can then be analyzed to identify problems.

- Modular diagnostic devices: These devices connect to the device and provide information about its condition.

- Web interfaces: Some Endress+Hauser instruments have web interfaces that allow access to their data and settings via a web browser.

1. Overview of diagnostic tools

PC Software

- FieldCare: This is a universal software that can be used with a wide range of endress hauser instruments. FieldCare can be used for instrument reading, calibration, setup and diagnostics.

- Memosens DAQS: This software is used to diagnose Memo sens sensors. Endress memosens can be used for sensor status checks, troubleshooting and calibration.

Modular diagnostic devices

- MultiCal: This is a universal diagnostic device that can be used with a wide range of Endress+Hauser instruments. MultiCal can be used for instrument reading, calibration, setup and diagnostics.

- SensorCal: This is a diagnostic tool used for sensors. SensorCal can be used for sensor health checks, troubleshooting and calibration.

Web interfaces

- Many Endress+Hauser instruments have web interfaces that allow access to their data and settings via a web browser. Web interfaces can be used to view device status data, identify faults, and change settings.

2. How to effectively use diagnostic tools

- Read the user manual: Before using any diagnostic tool, it is important to read its user manual. This will help you understand how to use the tool and how to interpret its results.

- Gather information about the problem: Before using diagnostic tools, it is important to learn as much as possible about the problem. This includes the symptoms of the problem, the conditions under which it occurred, and any other relevant information.

- Use the right tool: Choose the diagnostic tool that best suits your problem. For example, if you have a problem with a sensor, you should use a diagnostic tool designed for sensors.

- Follow the instructions: Follow the instructions given in the user manual of the diagnostic tool. This will help you use the tool correctly and get accurate results.

- Analyze the results: After using the diagnostic tool, analyze its results. This will help you determine the cause of the problem and take steps to correct it.

- If you cannot determine the problem: If you cannot determine the problem yourself, contact Endress+Hauser Technical Support. Support specialists will help you diagnose the problem and find a solution.

Using Endress+Hauser diagnostic tools can help you quickly and easily identify and troubleshoot your appliances. This will help you save time and money, as well as ensure continuity.

Conclusion

Understanding Endress+Hauser fault codes is critical for maintaining the efficiency, reliability, and safety of industrial automation systems. These codes serve as essential diagnostic tools, enabling quick identification and resolution of issues that can disrupt operations. By minimizing downtime and enhancing operational efficiency, fault codes help businesses avoid costly interruptions and maintain a competitive edge.

Proactive monitoring and interpretation of fault codes facilitate targeted troubleshooting, optimized performance, and reduced operational costs. Regular maintenance, informed by these codes, ensures equipment runs at peak efficiency, preventing minor issues from escalating into major problems. Furthermore, addressing fault codes promptly contributes to a safer working environment, safeguarding both equipment and personnel.

Endress+Hauser's commitment to innovation and quality is reflected in their comprehensive diagnostic tools and support resources, designed to empower users with the knowledge needed to keep their systems running smoothly. By leveraging these tools and understanding fault codes, companies can make data-driven decisions that enhance their overall process efficiency.

Eltra Trade have a vast selection of Endress+Hauser products and diagnostic tools at the best prices. Our inventory ensures you find exactly what you need, with worldwide delivery.