Ultrasonic flow meter working principle, how flowmeter works with gas and water

28.01.2021

Ultrasonic flow meter is a device that measure liquids or gases flow rate, using ultrasound signals.

CONTENTS:

- How does an ultrasonic flow meter work?

- Ultrasonic flow meter types

- Ultrasonic Doppler flow meters

- Transit time ultrasonic flow meter

- Clamp on (strap on) ultrasonic portable flow meter

- Ultrasonic open channel flow meter

- Ultrasonic flow meter installation

- Ultrasonic flow meter advantages and disadvantages

How does an ultrasonic flow meter work?

Ultrasonic flow meter principle is based on the use and analysis of ultrasonic waves. Such ultrasound is in the range above 20,000 Hz and can reach up to 1000 MHz.

There are several principles of flow rate measurement (it will be described below) but all systems have the same main sensing parts:

- Signal source

- Receiver

- Transducer (controller)

The principle of operation is based on a signal from the source that passes through stream and goes to receiver. Then it goes to the transducer, which analyzes result.

For such work, several pairs of sensors are usually installed. They are located against each other and exchange signals. The most often they are located diagonally from the pipeline axis.

Such an arrangement makes it possible to exchange sound signals both in the direction of the substance flow and against it. When pipeline is empty, both signals pass this distance with the same speed.

When the substance moves through pipe, the sound along the flow accelerates. Such impulse directed against the flow moves more slowly. The greater flow velocity, the greater the time difference between these signals.

The ratio of these values is proportional to the flow rate. Hence, if you know the pipe section dimensions and the substance characteristics, you can determine the flow rate.

Ultrasonic flow meter types

There are three main types of ultrasonic flowmeters depending on their working principle:

- Transit-time

- Doppler

- Open channel

Let’s look at each of them in detail.

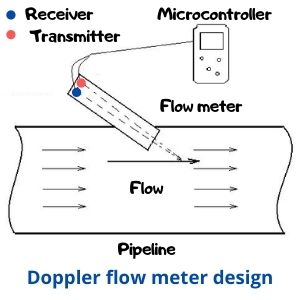

Ultrasonic Doppler flow meters

Doppler flow meters are operating, using Doppler Effect. In nutshell, this effect is based on the changing in sound waves coming from moving objects to the stationary position. You can observe this effect too, listening to the changing sound of the passing nearby car’s engine.

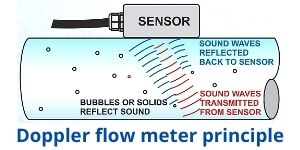

Doppler flow meter need a presence of solid parts or air bubbles to work. It has emitting transducer (signal source) and receiving transducer (receiver). The emitting transducer generates and sends ultrasound impulse. That impulse reflects from moving by solid parts or bubbles. The form of ultrasonic wave changes depending on velocity of the parts. Then the echo signal returns to the receiver. The device can determine speed of the entire flow by analyzing such waves.

The main plus of Doppler flow meters is their ability to work with solid parts and air bubbles in the stream. They are the most popular as blood and carbonated water flow meters.

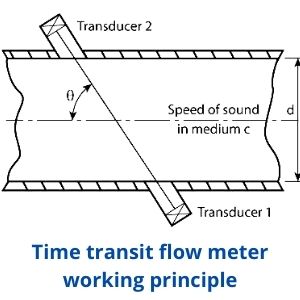

Transit time ultrasonic flow meter

Transit time flow meters measure velocity, calculating time of signal travel signal between two sensors. Such sensors are placed opposite each other and diagonally to the flow axis. There are two main methods:

Transit time flow meters measure velocity, calculating time of signal travel signal between two sensors. Such sensors are placed opposite each other and diagonally to the flow axis. There are two main methods:

- Diagonal mode

- Reflection Mode

Diagonal mode is method when sensors send signals directly to each other through the flow.

Reflection mode is method when signals from sensors are first reflected off the pipe’s wall and then sent to the opposite sensor.

Let's look at the principle using direct contact (diagonal mode) as an example. Each of the sensors works as a signal source and receiver. They send an ultrasonic pulse through the moving flow.

When sensors send the ultrasonic pulse through the moving flow they have different travel times depending on direction. Such signal accelerates when directed along the flow (upstream) and slows down when directed against it (downstream).

This difference in receiving time (∆ time) between two signals is proportional to the average flow velocity. When there is no flow in pipe, the travel time of both signals will be the same (∆ time = 0).

Transit time flow meters is an ideal solution for pure liquids or gases. The presence of solid parts or bubbles effects on its results. Transit time flow meters are used to measure gas, steam and vapors.

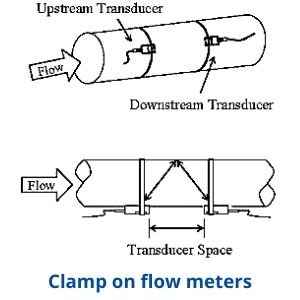

Clamp on (strap on) ultrasonic portable flow meter

There are two categories of flow meters according to the type of installation:

There are two categories of flow meters according to the type of installation:

- Inline

- Clamp on

Inline flow meter is device that mounting inside the pipeline system (this is described above).

Clamp-on flow meter (also called strap on) are portable compact device for measurements without interrupting in a pipeline. These flow meters are attached to the outer surface of the pipeline.

The most popular mounting approach for clamp flowmeters is V method with 2 paths. Two different sensors send two signals to each other. Such signals are directed diagonally into the wall of the pipe, from which it is reflected and hits the other sensor and vice versa. One of them moves upstream with higher speed and other moves downstream with lower speed. The trajectory of these waves looks like the letter V.

Clamp on ultrasonic flow meters will be an ideal solution for temporary measurements. It doesn't require mounting inside the pipeline, so it can be used with sanitary and corrosive and abrasive materials.

Ultrasonic open channel flow meter

Open channel flow meters are created for measuring level in open vessels or channels. Such sensor is mounted on the top above the flow. It sends high frequency ultrasonic sounds to the flow surface.

The pulses reflect from the surface and in the form of echo come back to the transducer. With reference to the speed of ultrasound in air, the current distance of liquid surface from the sensor can be calculated. Such results depend on from current air temperature level, that is open channels sensors commonly have built-in temperature sensors.

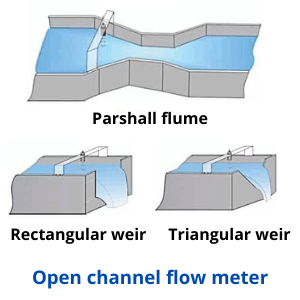

To measure flow rate with open channel flow meter you need an obstacle element (flume or weir). The sensor measures height of head of the liquid passes over such obstructions. Such flumes or weirs should have special shape (rectangular and v-notch weirs or parshall and palmer bowlus flumes). You can determine the flow rate, analyzing changes of level in these sections.

For open channels or partially filled pipes the portable Doppler meters are also can be used. They are also called as area velocity flow meters.

For such purpose, they are installed at the bottom of the channel. Ultrasound pulses are reflected off the water surface, air bubbles or solid particles.

Ultrasonic flow meter installation

It is necessary to meet a number of piping requirements for optimal installation of the ultrasonic flow meter. Equipment must be located far away from valves, bends and falling water to minimize turbulence. The ideal place for installation is a straight section of pipe with a distance of 10 pipe diameters before and 5 pipe diameters after the sensor.

Attention! Make sure that the liquid transmits ultrasonic waves normally (especially substances with a high level of density). In the case of a clamp on sensor, you need to make sure that the signal is strong enough to pass through the external pipe wall.

Ultrasonic flow meter calibration is carried out by manufacturer under standard conditions for the target medium (water, gas, oil, fuel). If your flowmeter operates under harsh conditions, then periodic calibration is required.

Ultrasonic flow meter advantages and disadvantages

Advantages:

- Lack of moving parts

- Low cost maintenance

- Clamp-on devices is used without penetration in a pipeline

- Ability to work with high pressure and temperatures

- High accuracy

- Parts do not obstruct the flow

- Ease to install

- Can work with large pipe diameters

Disadvantages:

- Sensitive to temperature changes, density, viscosity

- High price

- Clamp-on devices have lower accuracy

- Does not work well with very thick materials (slurry)

The pros and cons of an ultrasonic transducer depend greatly on the chosen type. For example, for a Doppler flow meter, the sediment of solids on the bottom wall of the pipe will not affect the result, but for travel time devices, it will be a problem.

Eltra Trade s.r.o. is an experienced ultrasonic flow meter distributor. We have a large catalog of Siemens ultrasonic flow meters (inline & clamp on) with the best price! If you have a question or need help with a choice feel free to call us or send a request.