Baumer Incremental encoder

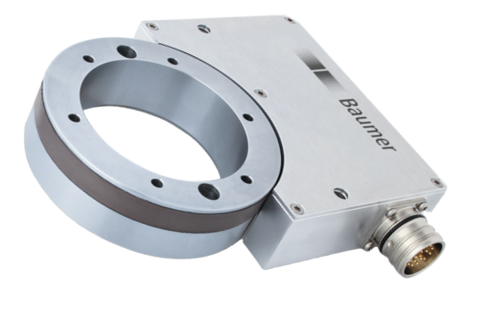

ITD 89H00 Rectangular Signal

- Through hollow shaft ø70 to ø140 mm

- Bearingless magnetic encoder

- Max. 8192 pulses per revolution

- Output circuits: HTL or TTL

- High accuracy - error max. ±0.1°

- Rotation speed max. 5000 rpm

ITD89H00 - Sine signal

- Through hollow shaft ø70 to ø140 mm

- Bearingless magnetic encoder

- 256 sinewave cycles per revolution

- Output circuit: Sine 1 Vpp

- High accuracy - error max. ±0.1°

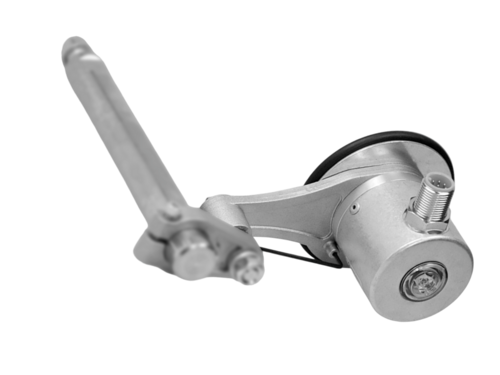

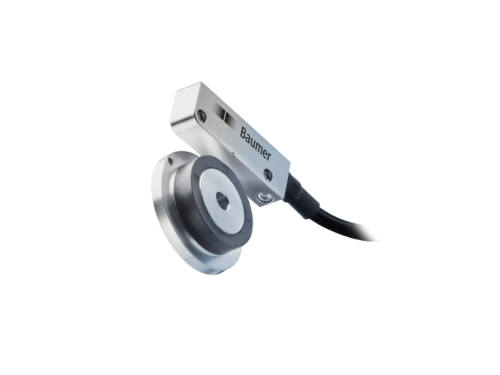

Incremental encoderMA20

- With measuring arm and wheel

- Encoder with 16 predefined resolutions

- Max. 25000 pulses per revolution

- Measuring wheel circumference 200 mm

- Manual adjustment without any programming tool

- Different degrees of rubber hardness for optimal grip

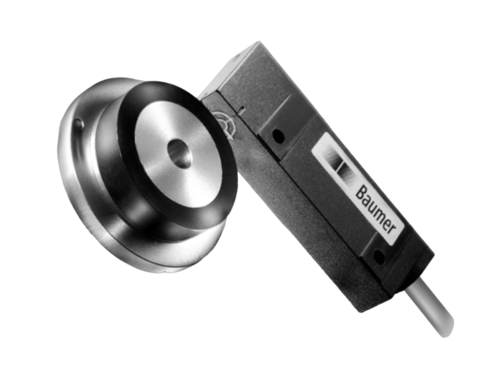

MDFK 08

- Magnetic sensor with magnetic wheel

- Resolution max. 4096 steps

- Output signals A 90° B or A 90° B +N

- Output circuits: push-pull and RS422

- Non-contact, wear-free sensing system

- Narrow mounting design

MDFK 08 - RS422

- Magnetic sensor with magnetic wheel

- Resolution max. 4096 steps

- Output signals A 90° B or A 90° B +N

- Output circuits: push-pull and RS422

MDFK 08G2101 S35A

- Shaft type: ø6...43.5 mm (through hollow shaft)

- Protection EN 60529: IP 67

- Working distance: < 0.6 mm

MDFK 08G2101 S35A - Combination of sensor / magnetic wheel

art. 10166037

- Current output

- Flylead Connector PUR M8, L=200 mm

- -40 ... 85 В°C

- IP 67

- Please order magnet separately

art. 10166036

- Current output

- Cable PUR 3 x 0.25, 2 m

- -40 ... 85 В°C

- IP 67

- Please order magnet separately

art. 10166033

- Voltage output

- Cable PUR 3 x 0.25, 2 m

- -40 ... 85 В°C

- IP 67

- Please order magnet separately

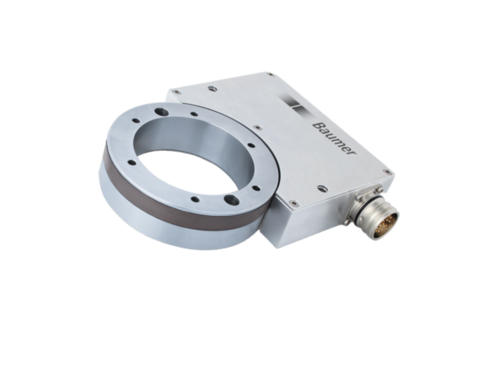

HDmag MHGE 100 Encoders without bearings - incremental

- Robust and wearless

- High protection through fully encapsulated electronics

- Large tolerances: axial ±3 mm, radial max. 2.2 mm

- Very compact dimensions

- Robust and wearless

- High protection through fully encapsulated electronics

- Large tolerances: axial В±3 mm, radial max. 2.2 mm

- Very compact dimensions

- Simple mounting, easy adaptation

- Robust and wearless

- High protection through fully encapsulated electronics

- Large tolerances: axial В±3 mm, radial max. 2.2 mm

- Very compact dimensions

- Simple mounting, easy adaptation

HDmag MHGP 200 Encoders without bearings - incremental

- Sensor head with integrated FPGA signal processing / Magnetic sensing

- Robust and wearless

- Electronics is fully encapsulated, high protection

- Large tolerances: axial ±3 mm, radial max. 2.2 mm

- Very compact dimensions

- Simple mounting, easy adaptation

- Several mounting possibilities

MHGP 100 Encoders without bearings - incremental

- Axial tolerance: ±3 mm

- Radial tolerance: 0.1...2.2 mm

- Degree of protection: IP 67

- Operating temperature: -20...+85 °C

- Material: Housing - aluminum alloy, wheel - stainless steel

art. 10136428

- cable FEP, 2 m

- -40 ... 120 В°C

Baumer MIL10 linear incremental encoder without bearings

- Sensor head with magnetic tape

- Robust magnetic sensing method

- Output signals A 90° B with index signal

- Output circuits: HTL/push-pull and TTL/RS422

- Resolution up to 5 µm (4-times evaluation)

- Non-contact, wear-free sensing system

- High resistance to dirt and vibrations

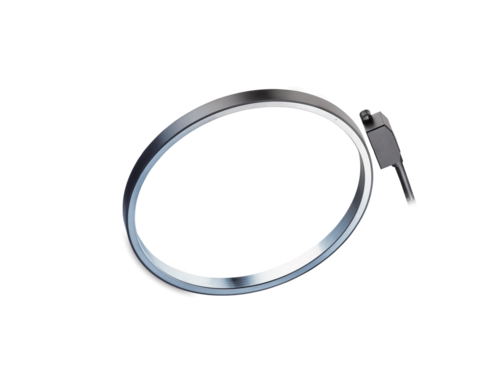

MIR 3000F - HDmag flex

- HDmag flex MIR 3000F Encoders without bearings - incremental

- Sensor head with magnetic tape for shaft ø300...3185 mm

- Encoder without bearings - incremental with magnetic sensing

- Square-wave signals HTL/TTL or sine signals

- Max. 131072 pulses per revolution

- Status indication via system OK output and LED

- Fully encapsulated electronics IP 67

HDmag flex MIR 350A Encoders without bearings - incremental

- Sensor head with split wheel and magnetic tape for shaft ø90...300 mm

- Encoder without bearings - incremental with magnetic sensing

- Split wheel design for easiest mounting on installed shafts

- Very large axial tolerances ±8 mm

- Max. 131072 pulses per revolution

- Status indication via system OK output and LED

- Fully encapsulated electronics IP 67

mir10

- Reading method: Magnetic

- Short circuit protection: Yes

- Supply voltage: 10...30 VDC

- Reverse polarity protection: Yes

og 71

- Encoder type: Incremental

- Detection method: Optical

- Body: aluminum

- Shaft: stainless steel

- Bearings: ball bearings

- Shaft diameter: 6 mm

- Shaft length: 15 mm

- Weight: 80 g

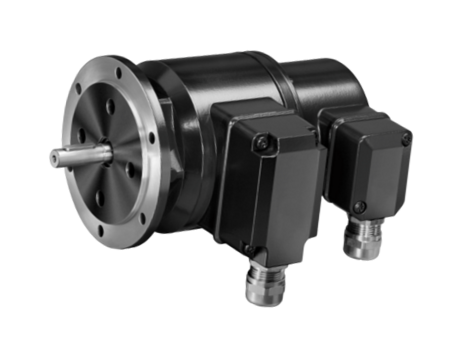

OG 8 Incremental encoder

- Solid shaft ø11 mm with EURO flange B10

- Optical sensing method

- EURO flange B10

- Output stage HTL or TTL

- Output stage TTL with regulator UB 9...26 VDC

The OG 9 from Baumer is an incremental encoder that is characterized by high reliability and accuracy. It is designed for use in heavy industry.

- Material: Housing - cast aluminum, shaft - stainless steel

- Operating temperature: -30...+100 °C (-25...+100 °C for >3072 pulses)

- Vibration resistance: IEC 60068-2-6 (10 g, 10-2000 Hz)

- Impact resistance: IEC 60068-2-27 (100 g, 6 ms)

- Corrosion protection: IEC 60068-2-52 (salt spray for C4 conditions according to ISO 12944-2)

- Explosion protection: II 3 G Ex ec IIC T4 Gc (gas), II 3 D Ex tc IIIB T135°C Dc (dust) (only with ATEX option)

- Weight: approx. 980 g

OG 90 incremental encoder

- Output signals: K1, K2, K0 + inverted

- Protection: IP 55

- Rotation speed: ≤12000 rpm

- Housing material: die-cast aluminum

og73

- Body materials: aluminum, powder coating

- Shaft materials: stainless steel

- Maximum rotation speed: up to 8000 rpm

- Incremental encoder (optionally programmable)

- HTL/TTL output driver for cable length up to 350 m

- Very high resistance to shock and vibrations

- Two-sided insulated bearing system with hybrid bearings

- Special protection against corrosion CX (C5-M)

- Large terminal box, turn by 180В°

- Function display via LEDs

pog 10

- TTL output driver for cable length up to 550 m

- High resistance to shock and vibrations

- EURO flange B10 / solid shaft ø11 mm

- Large terminal box, turn by 180°

Incremental encoders - combination

- TTL output driver for cable length up to 550 m

- Electronic speed monitoring

- EURO flange B10 / solid shaft ø11 mm

- Terminal boxes, turn by 180°

POG 10 + ESL 93

- TTL output driver for cable length up to 550 m

- EURO flange B10 / solid shaft ø11 mm

- Terminal boxes, turn by 180°

POG 10+ FSL is an incremental encoder

- Shaft type: ø11 mm solid shaft

- Permissible shaft load: ≤300 N axial, ≤450 N radial

- Temperature range: -40...+100 °C (optionally down to -50 °C)

- Protection: IP 66