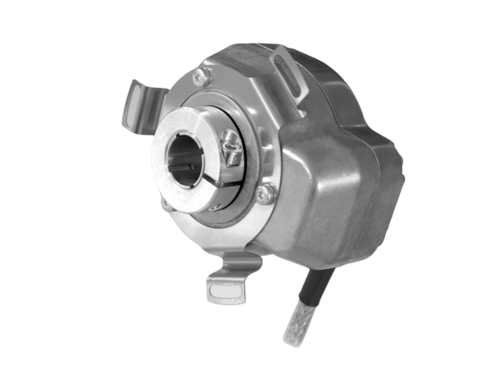

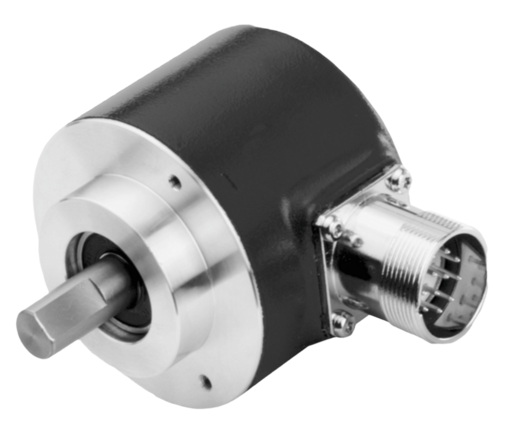

Baumer Incremental encoder

art. 11042716

- art. 11042716

- POG10 DN 1024 I Solid shaft with a diameter of 11 mm.

- Flanges EURO B10.

- Increased shock and vibration protection.

- Encoder diameter 115 mm.

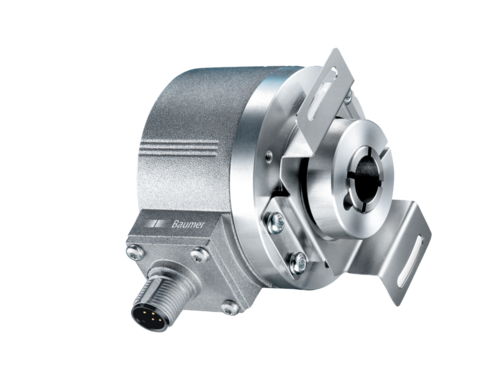

Incremental encoders - combination

- Twin encoder with two electrically separated systems

- TTL output driver for cable length up to 550 m

- EURO flange B10 / solid shaft ø11 mm

pog 11

- Size (flange): ø115 mm

- Shaft type: ø11 mm solid shaft

- Detection method: Optical

- Operating torque: 2 Ncm

- Mechanical speed monitoring based on centrifugal force

- Robust, compact housing

- Two bearings with large distance, one at each end

- High shaft load up to 350 N

- TTL output driver for cable length up to 550 m

- Terminal boxes, turn by 180В°

- Twin encoder featuring two separate systems

- Robust, compact housing

- Two bearings with large distance, one at each end

- High shaft load up to 350 N

- Shock resistant up to 300 g

- Highest operating speed 12000 rpm

- TTL output driver for cable length up to 550 m

- Terminal box, turn by 180В°

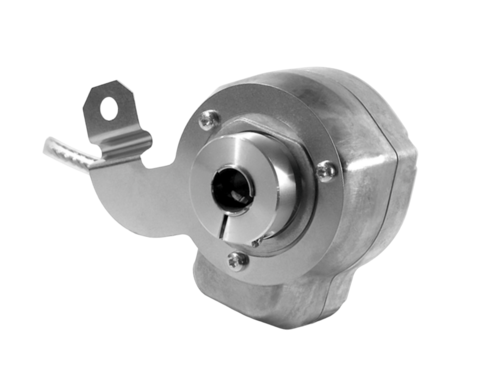

pog 9

- Housing material: Aluminum

- Shaft: Solid shaft ø11 mm

- Flange: EURO flange B10

- Moment of inertia: 100 g/cm²

- Maximum axial play: 0.2 mm

- Maximum radial play: 0.05 mm

Incremental encoders - combination

- TTL output driver for cable length up to 550 m

- Circuit breaker with one selectable threshold speed

- EURO flange B10 / solid shaft ø11 mm

- Terminal boxes, turn by 180°

Incremental encoders - combination

- TTL output driver for cable length up to 550 m

- Mechanical speed monitoring based on centrifugal force

- EURO flange B10 / solid shaft ø11 mm

- Terminal boxes, turn by 180°

pog 90

- Housing material: Aluminum

- Shaft material: Stainless steel

- Moment of inertia: 0.004 kgcm²

- Maximum axial play: 0.1 mm

- Maximum radial play: 0.05 mm

- Weight: 0.17 kg

art. 11076614

- art. 11076614

- 9-30 dc

- output signal format - htl / voltage output

art. 11076982

POG10G DN 1024 I / DN 1024 I Incremental encoders - combination

- Twin encoder, blind hollow shaft, 1024 pulses per revolution

- HTL output driver for cable length up to 350 m

- Very high resistance to shock and vibrations

- Double-side bearing with hybrid bearing for extended service life

- Large terminal box, turn by 180°

Baumer TIL

- Through hollow shaft ø10 to ø16 mm

- Max. 2048 pulses per revolution

- Optical sensing method

Baumer TIL Y 1

- Blind hollow shaft ø12 mm

- Max. 2048 pulses per revolution

- V-Lock clamping

- TTL or HTL output signals

art. 11116859

Mini Optical Incremental Encoder

art. 10153305

- Incremental hollow shaft encoder

- Size (flange): ø58 mm

- Shaft type: ø12 mm (blind hollow shaft)

- Reading method: Optical

- Housing material: Aluminum

art. 11113010

- Encoder with blind or through hollow shaft ø12 mm

- Optical sensing method

- Max. 5000 pulses per revolution

- Small profile depth

art. 10153169

| Max. speed | 12,000 rpm |

| Frequency limit | 50 kHz |

| Supply voltage | 10...30 Vdc |

Programmable Incremental Encoder with through hollow shaft

EIL580P-TT14.5FF.01024

- Size ø58 mm

- Precise optical sensing (interpolated)

- Output signal level programmable (TTL)

- Through hollow shaft, ø14 mm

- Flange connector M23, 12-pin CCW, radial

- Pulses per revolution 1...65536, programmable

gi355

- Encoder with solid shaft ø10 mm or ø6 mm

- Max. 6000 pulses per revolution

- Optical sensing method

- Clamping or synchro flange

- Industrial standard

- High rotation speed up to 10000 rpm

gi355 encoder

- Resolution: 500 pulses per revolution

- Measurement method: optical

baumer gi355

- Measurement method: optical

- Shaft material: stainless steel

- Body material: aluminum

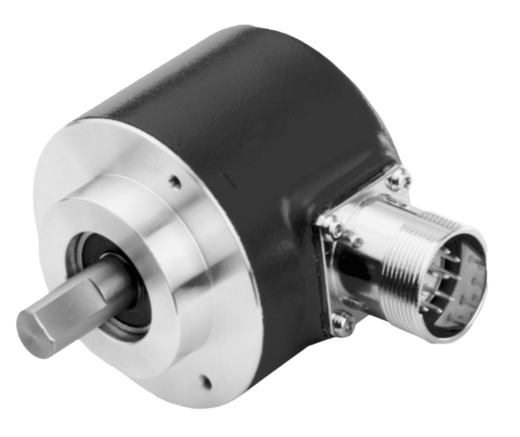

Encoder

HOG 10 DN 1024

- HTL output driver for cable length up to 350 m

- Mechanical speed monitoring based on centrifugal force

- Double-side bearing with hybrid bearing for extended service life

- Terminal boxes, turn by 180°

Incremental encoders

- Blind hollow shaft ø16 mm

- Approval DNV

- High protection IP 67

- TTL output driver for cable length up to 550 m

art. 11075478

- 11075478

- 9-30 DC

- -40…+100

art. 11098378

- food - 9-30 dc

- output signal format - htl / voltage output

art. 11169777

- art.11180095

- food - 9-30 dc;

- output signal format - ttl / rs-422

art. 11138861

Incremental encoder

art. 11183231