Magnetic vs. Optical Encoders – Which One is Right for You?

01.04.2025

In modern automation and motion control systems, encoders play a crucial role, providing accurate measurement of position, speed, and direction of motion. Before choosing a device, it is necessary to consider various parameters, since the accuracy of the system and its reliability, service life and resistance to external influences depend on the correct choice.

In this article, we will consider the main differences between optical vs magnetic sensing encoders, their advantages and limitations, and also provide an encoder selection guide that will help you choose the best solution for your task.

CONTENT:

- What Are Encoders?

- Magnetic Encoders – How They Work

- Optical Encoders – How They Work

- Differences Between Magnetic and Optical Encoders

- Which Encoder Should You Choose?

- Applications of Magnetic and Optical Encoders

- Conclusion

What Are Encoders?

Encoders are devices that convert mechanical movement into electrical signals, allowing the control system to determine the position, speed, and direction of an object's movement. They are indispensable in drive systems where accuracy and stability are critical.

When choosing an encoder, you should consider several parameters:

- Resolution: determines how accurately the device can measure movement. The higher the resolution, the more accurate the positioning;

- Reliability and durability: the ability of the device to withstand loads, vibrations, and other mechanical impacts;

- Resistance to external conditions: protection from contamination, temperature fluctuations, and electromagnetic interference;

- Measurement accuracy: a critical parameter for many tasks that directly affect the efficiency of the system. Encoder accuracy can vary significantly depending on the type of device.

Depending on the operating technology, there are several encoder types, among which magnetic and optical models are the most common.

Magnetic Encoders – How They Work

Magnetic encoders work by measuring the change in the magnetic field created by a special disk. They include three main components:

- Magnetic disk: a rotating element with alternating magnetic zones;

- Hall sensor or magnetoresistive sensor: detects changes in the magnetic field and converts them into an electrical signal;

- Data processor: interprets the signal and transmits it to the control system.

There are two main type of encoders in this category: incremental and absolute. A magnetic incremental encoder transmits changes in position as pulses, while an absolute encoder records the exact position at any given time.

Advantages of Magnetic Encoders

Let's take a look at the advantages offered by magnetic encoders:

- Resistance to contamination. Unlike optical models, magnetic encoders do not require a clean working environment. They continue to operate even when exposed to dust, dirt, or moisture, making them ideal for industrial use;

- Reliability in harsh conditions. Such devices can withstand vibrations, shocks, and temperature changes, so they are used in difficult industrial environments. Industrial encoders comparison shows that magnetic models are more resistant to external influences;

- Cost-effectiveness and durability. Magnetic encoders have a simple design, which reduces their cost and makes them durable;

- No need for optical visibility. Since the operation is based on a magnetic field, the device does not require strict alignment or an exact line of sight, as in optical models.

Limitations of Magnetic Encoders

Now let's learn more about their limitations:

- Lower resolution compared to optical encoders. Magnetic encoders are inferior in accuracy to optical analogs, especially in tasks that require high detail;

- Susceptibility to magnetic interference. Strong electromagnetic fields can affect the accuracy of measurements, so such devices require protection from external influences;

- Less precise for high-speed applications. For high-speed processes, data accuracy may decrease, making them less suitable for precision equipment.

Optical Encoders – How They Work

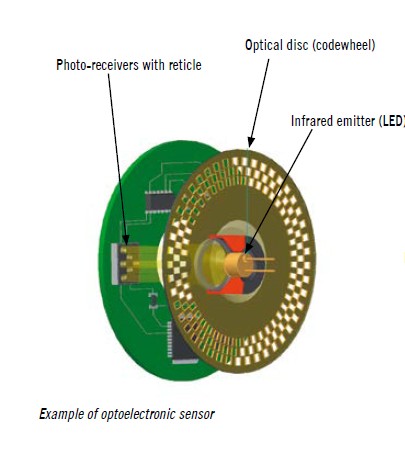

Optical encoders use light to determine position. They are constructed using the following elements:

- LED: a source of light that passes through a disk;

- Code disk: a disk with transparent and opaque zones that generates light pulses;

- Photodetector: records changes in light and converts them into digital signals;

- Processor: interprets the data and transmits it to the control system.

Like magnetic models, optical encoders are available in incremental and absolute versions. Optical encoders are widely used in applications where accuracy and stability are critical.

Advantages of Optical Encoders

Let's learn about the advantages of optical encoders:

- High accuracy. High-resolution motion control is a key advantage of optical models. They provide the accuracy required for complex automated processes;

- Excellent performance at high speeds. Optical encoders are capable of transmitting data at high frequencies, making them ideal for high-speed systems;

- Insensitivity to magnetic fields. Unlike magnetic models, optical devices are not affected by electromagnetic interference.

Limitations of Optical Encoders

Despite their high accuracy, optical encoders have several limitations:

- Sensitivity to contamination. Dust, dirt, and oil can block the light beam, causing measurement errors or device failure;

- Line-of-sight requirement. To accurately read data, light must pass without obstructions, making encoders vulnerable to contamination;

- High cost. Optical encoders are more difficult to manufacture and calibrate, which increases their price;

- Limited resistance to harsh conditions. They are sensitive to vibration, shock, and humidity, making them less reliable than magnetic encoders.

Differences Between Magnetic and Optical Encoders

To finally understand the differences between magnetic vs optical encoders let's look at the table below.

Which Encoder Should You Choose?

The choice between a magnetic encoder vs optical encoder depends on operating conditions, accuracy requirements, and budget. Let's consider in which cases it is worth giving preference to each type.

Choose magnetic encoders if:

- You need to work in harsh conditions (dirt, moisture, vibration). Magnetic encoders are great for harsh industrial environments, as they are resistant to dirt, moisture, and mechanical stress. Unlike optical analogs, which require a clean working environment, magnetic models continue to work even if dirt or dust gets on their elements;

- Affordable prices are important. If the budget is limited, magnetic encoders are a cost-effective solution. Their design is simpler and production is cheaper compared to optical models. At the same time, they provide sufficient accuracy for most industrial and automated applications;

- You need a durable option. Due to their high resistance to external influences, magnetic encoders have a long service life. They can operate in conditions of sharp temperature fluctuations, mechanical shocks, and vibrations, which makes them the best encoder for industrial applications.

Choose optical encoders if:

- You need extreme accuracy. Optical encoders have high resolution and provide accurate determination of position, speed, and direction of movement. This makes them ideal for applications where high-precision measurements are critical, such as precision engineering, robotics, and scientific research;

- The system operates in a clean environment. Optical encoders are sensitive to contamination, as they rely on a light signal passing through the code disk to operate. Any dust, oil, or condensation can distort the data, making them less suitable for harsh environments;

- High-speed operation is important. If your system operates at high speed, it is important that the encoder can transmit signals without delays or distortions. Optical models provide instant response and accurate data readings even with extremely fast movements, making them the best choice for automated manufacturing, high-speed robots, and CNC machines.

Applications of Magnetic and Optical Encoders

Encoders are used in many industries, and the choice of technology depends on the specifics of the equipment operation.

Application of magnetic encoders:

- Heavy equipment. In the construction and mining industries, these types of encoders for motors are needed where the equipment operates in harsh conditions: dust, dirt, vibration, temperature changes, and impacts;

- Robotics in harsh conditions. In industrial and mobile robots operating outdoors or in an aggressive environment, magnetic encoders provide reliable position and motion reading, even if there is a lot of dirt around. They are used in agricultural robots, automated logistics systems, and autonomous vehicles;

- Wind turbines and other outdoor installations. In renewable energy systems, magnetic encoders help track the position of wind turbine blades and optimize their operation. They withstand moisture, low temperatures, and strong winds, ensuring the stable operation of the equipment;

- Automotive sensors. In the automotive industry, magnetic encoders are used in steering systems, anti-lock braking systems (ABS), and other components that require reliable position and speed detection. Their resistance to dust, vibration, and temperature changes makes them an ideal solution for vehicles.

Optical encoder applications:

- CNC machines and 3D printers. In high-precision manufacturing, where absolute precision of tool positioning is required, optical encoders are used. They ensure perfect line sharpness on CNC machines and precise material feed in 3D printers, which is especially important for complex product geometries;

- High-speed robots. In modern robotic systems, for example, in assembly lines of automobile plants, high speed and precision of movement are required. Optical encoders allow robots to perform manipulations with minimal delays, which increases productivity and reduces the likelihood of errors;

- Semiconductor and medical equipment. Microchip manufacturing, surgical robots, and laboratory analyzers require maximum precision and stability. Optical encoders help control the movement of mechanisms with nanometer precision, ensuring the reliability and repeatability of results;

- Precision manufacturing. In the aviation, space, and scientific industries, measurement accuracy plays a decisive role. Optical encoders are used in measuring machines, coordinate measuring machines (CMM), and other devices where high resolution and stability of operation are required.

Conclusion

The choice between an optical vs magnetic encoder depends on the operating conditions, accuracy, and budget. Magnetic models are reliable and affordable, while optical ones provide the highest accuracy.

If you are looking for the best encoder for industrial applications, explore our selection of encoders at ELTRA TRADE for your automation needs!