Pepperl+Fuchs

Choose a subcategory:

Show all categories

- Interface between the I/O modules and the PCS/PLC

- Com unit for 80 analog or 184 digital channels

- Communication via MODBUS TCP

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- HART communication via MODBUS TCP or service bus

- Configuration via FDT 1.2 DTM

- Non-volatile memory for configuration and parameter settings

- Self configuration in redundant systems

- Permanently self-monitoring

- Outputs drive to safe state in case of failures

- Module can be exchanged under voltage

- Interface between the I/O modules and the PCS/PLC

- Mounting in Zone 2, Class I/Div.2 or in the safe area

- Non-volatile memory for configuration and parameter settings

- Communication via PROFINET

- HART communication via PROFINET and HART I/P

Vibration Limit Switch

- Surge protection barrier for 2 signal lines

- Nominal voltage 24 V DC

- Surge protection barrier for grounded signal lines

- Max. surge current (8/20 ?µs) 20 kA

- Connection via screw terminals

- DIN rail mountable

- Up to SIL 3 acc. to IEC/EN 61508

- Surge protection for 4 supply lines

- Type 2 acc. to EN 61643-11

- For TN-S systems (230 V AC/400 V AC)

- Pre-wired unit

- Operating state and fault indication of every protected line

- Fault indication output

- DIN rail mountable

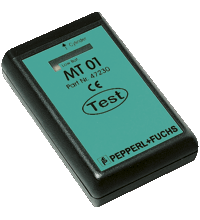

- No contact with test object required

- Highly sensitive tip

- Resistent to dirt

- Optical indication

- Built-in test magnet for self-test and battery control

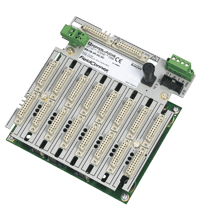

- 4 segments, redundant, individual modules per segment

- Customized for Honeywell, C-Series

- High-power trunk: Live work on devices in any hazardous area

- Optimized for size and quality, low heat dissipation

- For FOUNDATION Fieldbus H1

- Optional advanced diagnostics

- Passive impedance and CREST technology for high reliability

- Installation in Zone 2/Div. 2

Battery operated

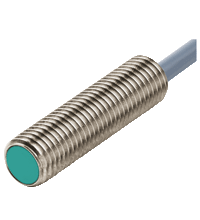

Inductive sensor

- 4 mm flush

- Increased operating distance

- Extended temperature range

-40 ... +85 ?°C

Inductive sensor

Inductive sensor