Burkert process and control valves. How to choose process valve?

12.01.2020

Bürkert made a wide range of modular valves series for controlling processes. The company produces various equipment with different operating principles, control systems, and designs.

CONTENTS:

- What is a burkert valve?

- Burkert valve types

- Valve actuators and controls

- Choosing Bürkert technological valve

- Where to buy burkert valves?

What is a burkert valve?

The main advantage of Burkert is the release of valves with a modular structure. This feature allows user to choose the most suitable configurations for required conditions and regional standards. It makes the series very flexible and customize.

There is the opportunity for the client to choose a number of variants of actuators, materials and regulation elements. Let's look at the main categories of burkert valves.

Burkert valve types

The company manufactures all parts in its own factories. The research groups of the concern are constantly working on their improvement. Moreover, due to such approach, experts check and measure the quality of materials and products at all stages of production. This option allows the customer to implement the wishes already at the stage of development and production.

Device selection always starts with its body. Its whole operation principle is mostly dependent on its housing design. The buyer should pay particular attention to the sort of flow materials with which the equipment will service.

Device selection always starts with its body. Its whole operation principle is mostly dependent on its housing design. The buyer should pay particular attention to the sort of flow materials with which the equipment will service.

There are special solutions for a number of industries: food & beverage, pharmaceutical, material processing, water treatment, etc. For example, pneumatic systems have their own requirements.

The choice of right type also depends on the physical and chemical properties of the medium (viscosity, temperature, and pressure).

In total, Burkert produces 4 main types of housings for process valves:

- Angle seat

- Ball

- Globe

- Diaphragm

The design of the case, in turn, is divided into two main categories. It depends on regulation requirements. Valves are available for both continuous and shut off control.

Angle seat valves

Angle seat process valves are the most common and easiest class of equipment for flow management. About the most popular model of angle seat valve you can read here: Burkert Type 2000.

Angle seat valve for continuous control works on the principle of «fit and forget». It does not require constant repair and maintenance.

Angle seat on/off valve quickly stops the flow, via closing the pipeline. Such devices have a high level of tightness and safety. It is the simple solution for on/off and process control applications.

Angle seat on/off valve quickly stops the flow, via closing the pipeline. Such devices have a high level of tightness and safety. It is the simple solution for on/off and process control applications.

Devices are available with port connection sizes from ½ inches (12,7 mm) up to 2 ½ inches (63,5 mm). The basic body materials are stainless steel and gunmetal. Standard connection types are NPT (national pipe thread), and weld or clamp ends.

There are two main options for placing these items. For materials that are easy to compress (air, vapors, gases), you can use the flow direction directly under the seat. This feature will save even more space in working zones. For water, oil, and other high-density media, it is best to place the flow over the seat (for operation without water hammer).

Burkert angle seat valves are a low-cost simple solution with high life cycle.

Globe valves

Globe continuous control valves are practical and reliable devices for industrial systems. Such devices are attached to the pipes using flanges. Standard connections for this type is ANSI flange.

Globe shut off valves are a standard regulatory process tool. The manufacturer equips them with a light and compact body to save space and to reduce the weight. Products are available with both metal and soft seals. These devices have 5 million life cycles in fluids and 1 million in steam. Each model has one of several connection options. Basic material for such assembly is cast stainless steel 316L.

Burkert Globe valves provide the best range of control in the category. They are commonly used for both gas and liquids.

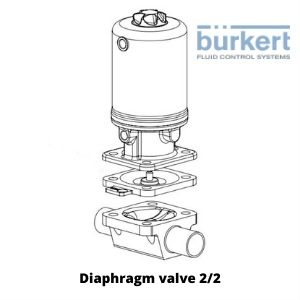

Diaphragm valves

Diaphragm continuous control valves have special design with media separation. They are quite popular in working with corrosive and abrasive substances. Such series are often used in areas with high hygiene requirements (medicine, food, drinking water etc.). The company produces a series of unique hygienic valves for these industries.

Diaphragm continuous control valves have special design with media separation. They are quite popular in working with corrosive and abrasive substances. Such series are often used in areas with high hygiene requirements (medicine, food, drinking water etc.). The company produces a series of unique hygienic valves for these industries.

The main structural detail is a membrane. It separates the flow from the main valve components. Various sorts of materials (EPDM, PTFE, GYLON etc.) are available depending on the purpose.

Diaphragm shut off valves control both ultra-pure and viscous materials. They provide minimal contact with the medium and have a small dead volume.

Burkert diaphragm valves the most optimal solution for applications with high hygienic and sanitary demands.

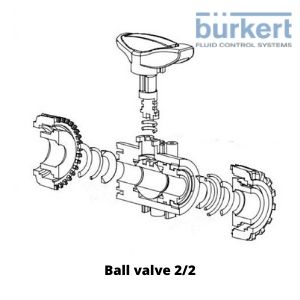

Ball and butterfly valves

Ball valves perform the function of regulation in pipes with medium diameters (for example, with oil and gas). It is available in sizes from ¼ inch (6,35 mm) up to 8 inches (203,2 mm). Their life cycle is in the range from 250.000 to 500.000 cycles before it begins to leak.

They are mainly used for isolation. Standard materials are similar to the first two categories. Ball valves are rated up to 1200 psi.

Butterfly valves are also used for piping applications and have a disc-shaped control element. They are available with port connections of sizes from ½ (12,7 mm) to 48 inches (1.22 m). They are primarily operate in large diameter pipelines. Standard connection are ANSI, wafer and lug style flanges. The basic body materials are cast iron, ductile iron and cast stainless steel.

Valve actuators and controls

After selecting the type of the body, the customer needs to choose control parts and actuators. It is necessary to determine which model will correspond to the functioning of a particular production process.

Bürkert manufactures several main actuator types:

- Manual

- Pneumatic

- Electric

- Electromotive

The concern also created its own actuator ELEMENT with FreshAir technology, which is an upgraded version of the classic models. Besides, to the basic ones, there are various additional versions (“dual” for example).

After choosing actuator, the consumer needs to pay attention to the regulation and data control options. The manufacturer produces devices with both centralized and decentralized control.

The concern's assortment also includes positioners, valve islands, sensors, controllers, switches, pumps and many other additional equipment for flow and mass management services. Additional parts will significantly upgrade quality and accuracy level. With correctly selected all the necessary details, the user will be able to configure the most efficient work.

Choosing Bürkert technological valve

Choosing the right Bürkert technological valve involves several key considerations to ensure it meets your specific application requirements. Here’s a detailed guide to help you make an informed decision:

1. Understand Your Application Requirements

- Medium: Identify the type of fluid (liquid or gas) that will flow through the valve. Consider its properties such as viscosity, corrosiveness, and temperature.

- Flow Rate: Determine the required flow rate and pressure drop across the valve.

- Operating Conditions: Consider the operating temperature and pressure conditions of your system.

2. Valve Type Selection

- Bürkert offers a variety of valve types, each suited for different applications:

- Solenoid Valves: Ideal for on/off control of fluids. Suitable for applications requiring quick response times.

- Process and Control Valves: Used for precise control of fluid flow. These include globe valves, diaphragm valves, and angle seat valves.

- Ball Valves: Suitable for applications requiring a tight shut-off and high flow capacity.

- Proportional Valves: Provide variable control of flow rates and are ideal for applications requiring fine adjustments.

3. Material Compatibility

- Valve Body Material: Choose a material compatible with the medium. Common materials include stainless steel, brass, and plastic.

- Seal Material: Ensure the seal material is compatible with the medium to prevent leaks and ensure longevity. Options include EPDM, PTFE, and FKM.

4. Actuation Method

- Manual: Simple and cost-effective for applications where automation is not required.

- Pneumatic: Suitable for applications requiring fast and reliable actuation.

- Electromotive: Provides precise control and is ideal for applications requiring fine adjustments.

5. Control and Feedback Options

- Positioners and Controllers: For applications requiring precise control, consider valves with integrated positioners or controllers.

- Feedback Systems: Ensure the valve has the necessary feedback systems (e.g., limit switches, position sensors) to monitor valve status.

6. Sizing and Configuration

- Flow Coefficient (Kv/Cv): Use Bürkert’s valve sizing tools to calculate the appropriate flow coefficient for your application1.

- Connection Type: Choose the appropriate connection type (threaded, flanged, welded) based on your system requirements.

7. Compliance and Certifications

Ensure the valve meets industry standards and certifications relevant to your application (e.g., FDA, ATEX).

By following these steps, you can ensure that you select the most suitable Bürkert valve for your specific needs.

Consequences of Incorrect Technological Valve

Selecting the wrong technological valve for an industrial application can lead to several serious consequences, impacting both the efficiency and safety of the system. Here are some potential issues:

1. System Inefficiency

- Flow Restriction: An incorrectly sized valve can restrict flow, leading to reduced system performance and efficiency.

- Pressure Drop: A valve that is too small can cause a significant pressure drop, affecting the overall operation of the system.

2. Operational Failures

- Leakage: Using a valve with incompatible materials can result in leaks, which can be hazardous and lead to product loss.

- Valve Sticking or Jamming: If the valve is not suitable for the medium or operating conditions, it may stick or jam, causing operational disruptions.

3. Safety Hazards

- Overpressure: An improperly selected valve might not handle the system’s pressure, leading to overpressure situations that can cause equipment failure or even explosions.

- Corrosion and Erosion: Using a valve made from materials that are not compatible with the medium can lead to corrosion or erosion, compromising the integrity of the valve and potentially causing dangerous leaks.

4. Increased Maintenance and Downtime

- Frequent Repairs: Incorrect valve selection can lead to frequent breakdowns and repairs, increasing maintenance costs and downtime.

- Shortened Lifespan: A valve that is not suited for the application will wear out faster, necessitating more frequent replacements.

5. Economic Impact

- Higher Operational Costs: Inefficiencies and frequent maintenance can lead to higher operational costs.

- Product Loss: Leaks and operational failures can result in significant product loss, impacting profitability.

Choosing the right valve is crucial for the smooth and safe operation of any industrial system.

Where to buy burkert valves?

For a comprehensive selection of Bürkert valves, look no further than the Eltra Trade website. Here’s why Eltra Trade is the best choice for your valve needs:

- Extensive Selection: Wide variety of Bürkert valves to suit any application.

- Expert Guidance: Our knowledgeable managers are always available to help you choose the right valve and answer any questions you may have.

- Reliable and Fast Delivery: We ensure reliable and fast delivery worldwide, so you receive your products promptly.

- Competitive Pricing: Enjoy great prices on all our products.

Visit our website today to find the perfect Bürkert valve for your needs!