Pepperl+Fuchs

IN STOCK!!!

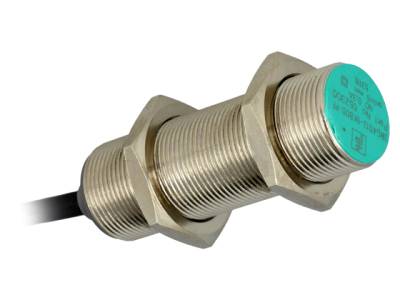

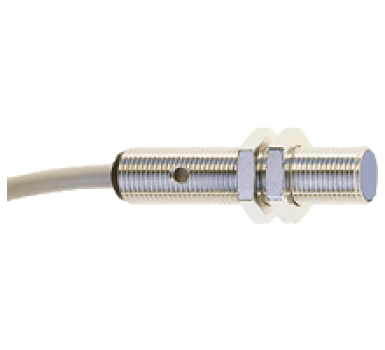

Pepperl Fuchs NBB20U1UU non-contact inductive sensor

- art. 238884

- Diagnostic Coverage (DC)0 %

- Sensor head bidirectional and rotatable

- NO/NC selectable

- Comfort series

IN STOCK!!!

- art. 191136

- UL approvalcULus Listed, General Purpose, Class 2

- Power Source/Analog output: 0 V ... 10 V/4 mA ... 20 mA

- Measuring range: 0 ... 120 mm

- M12 (4-pin)

- Resolution: 0.125 mm

3rg4013

- Sensitivity: from 0.1 to 100 mm

- Operating range: 10 to 1000 mm

- Response time: from 0.1 to 100 milliseconds

- Noise level: from 0.1 to 100 millivolts

- Body: stainless steel or polycarbonate

Pepperl Fuchs NBB0

- Detects metal objects at a distance of 0.2 mm to 100 mm.

- Operate in the temperature range from -40 °C to 70 °C.

- Voltage range: 12 V to 24 V.

- Consume current from 1 mA to 20 mA.

- Protection class IP67

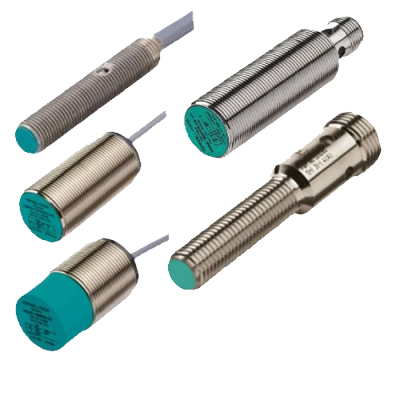

Pepperl+Fuchs NBB1 inductive sensors

- High reliability

- Durability

- Wide range of functions

- High accuracy

- Small size

NBB10 industrial inductive sensors

- Distance measurement accuracy up to 0.5 mm

- They operate in the temperature range from -40 to +85 °C.

- They are installed by flush mounting.

- Protected against water and dust.

- International standards for use in explosive atmospheres.

Inductive sensors of the NBB15 series

- Available in a wide range of specifications

- Highly reliable and durable

- Integration with Industry 4.0, wireless communication.

IN STOCK!!!

- art. 194767

- Sensor head bidirectional and rotatable

- 15 mm flush

- 4 LEDs indicator for 360° visibility

- Sensitivity: from 2 to 100 mm

- Working distance range: wide

- Resistance to contamination: high

- Easy installation and maintenance: high

nbb4

- Explosion protection class: Ex ia, Ex d

- Protection class against dust and moisture: IP68 / IP69K

- Wide range of performance characteristics

- Ability to operate in hazardous areas

Pepperl+Fuchs NBB5

- Provide high switching accuracy

- Designed for operation in harsh environments

- Available in a wide range of operating distances

- Have a high level of protection against dust and moisture

Pepperl Fuchs NBN12 Sensors

- Operate in a wide temperature range

- Wide range of supply voltages

- Wide range of detection distances

- Fast response time

- Protected against dust and water

NBN15 industrial inductive sensors

- High reliability and durability

- High accuracy of metal object detection

- Used in various industries

- Among the most affordable inductive sensors on the market

NBN25 inductive sensors

- High accuracy

- Low cost

- Wide range of additional options

nbn3

- Long operating range

- High sensitivity

- Wide operating temperature range

- High resistance to contamination

NBN4 sensors are used for:

- Level control

- Position control

- Absence of objects

- Size of objects

nbn40

- Low cost

- Easy integration

- Wide range of options

- Durability

NBN7 sensors are used:

- Liquid level control

- Monitoring the presence of objects

- Monitoring the position of objects

- Control of the speed of objects

- Product quality control

NBN8 inductive sensors

- Made of high quality materials

- Provide high measurement accuracy

- Used in various industries

- Easy to install and maintain

NCB5 inductive sensors

- Flexible end piece

- Metal end element

- Extended sensing area

- High sensitivity

IN STOCK!

Connection 5 m fixed cable

3rg4012

- Self-diagnostic function

- Temperature compensation function

- Function of adjusting the working gap

3rg4014

- Control of small objects

- Control of objects of different sizes

- Monitoring objects in changing environments

- Monitoring objects in explosive environments

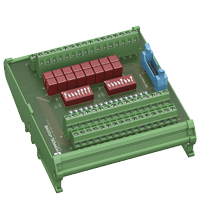

- Connection board for K-System HART Multiplexer

- 16-channel

- Interface for series connection or parallel connection

- Integrated, switchable 220 Omega- resistor

This item is out of production!

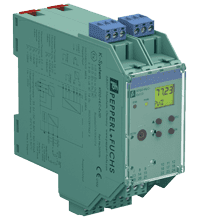

- 4-channel isolated barrier

- 24 V DC supply (bus powered)

- Dry contact or NAMUR inputs

- 4 passive transistor outputs

- Line fault detection (LFD)

- Up to SIL 2 acc. to IEC 61508

- LED status indicator of bus communication and read/write heads

- Max. 2 read/write heads can be connected

- Alternatively 1 read/write head and 1 trigger sensor can be connected

- Multiprotocol-compatible

- M12 power connector

- Sturdy metallic housing

- Web-based configuration

- Operating frequency 13.56 MHz

- Conforms to ISO 15693

- Suitable for FRAM transponder

- Read/write head with thread M18 x 1

- Connection via V1 (M12 x 1) plug connection

- Multihole-LED for function display

- Degree of protection IP67

- For connection to IDENTControl control interface

- 1-channel isolated barrier

- 24 V DC supply (Power Rail)

- Thermocouple, RTD, potentiometer or voltage input

- Current output 0/4 mA ... 20 mA

- Sink or source mode

- Configurable by PACTware

- Line fault (LFD) and sensor burnout detection

- Up to SIL 2 acc. to IEC 61508/IEC 61511

- 1-channel isolated barrier

- 24 V DC supply (Power Rail)

- HART field device input with transmitter power supply

- Usable as signal splitter (1 input and several outputs)

- 3 analog outputs 4 mA ... 20 mA

- Sink and source mode output

- Configurable by keypad

Pepperl + Fuchs is a leading sensor production company not only in Germany but also throughout the World.

The presentation of Pepperl+Fuchs catalog you can see here: P+F overview pdf ![]()

Peperl + Fuchs GMBH

Walter Pepperl and Ludwig Fuchs founded the company in 1945. At first, it was just an ordinary radio repair shop. However, after three years, the company completely changed a direction of development and began to produce own electronic products.

Already in 1958, the company released its first equipment. These devices were non-contact switching and transistor amplifier (with an intrinsically safe control circuit). One of the main reasons for its rapid growth was the constant attention to customer desires and modern requirements.

Peperl+Fuchs Inc

The main directions of the company's development are industrial sensors, explosion protection and intrinsic safety.

More than 6300 employees work here. P + F has its subsidiaries and representative offices in more than 80 countries. The company's revenue in 2018 amounted to 715 million euros. Pepperl Fuchs distributors deliver equipment worldwide.

Pepperl & Fuchs products

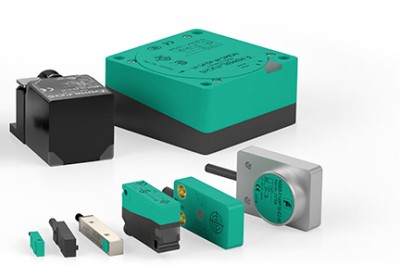

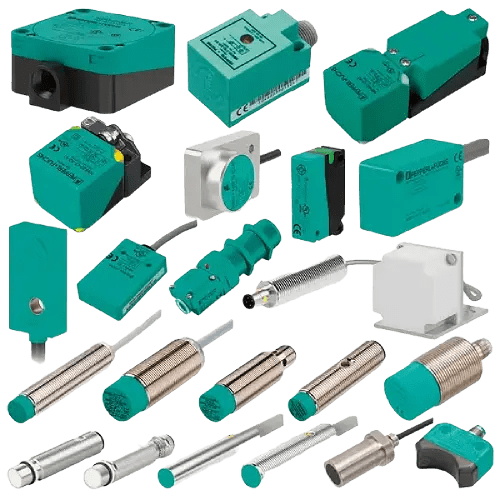

Industrial sensors are the most popular P + F product. That category is divided into several large groups by type:

- Proximity Sensors

- Photoelectric Sensors

- Rotary Encoders

- Ultrasonic sensors

- Industrial Vision

- Positioning Systems

- Inclination and Acceleration Sensors

- Industrial Communication

- Identification Systems

- Displays and Signal Processing

- Connectivity

Proximity sensors is a category that brings together dozens of different series. Here are just the main ones: inductive, capacitive, magnetic field. The producer also manufactured additional parts and accessories. Company produces equipment for almost any contactless applications.

Photoelectric sensors is also a category including a bunch of diverse series. All of them are able to perform various tasks using an optical beam. Such equipment determines a distance, movement and even color of different objects in non-contact way. Customers may choose the most suitable model for himself among the many variations.

Industrial vision consists of both sensors and special vision systems. P + F offers its clients a wide range of products from barcode imagers to a number of vision sensors.

Ultrasonic sensors may work at any places but without existence of sound interference. Due to ultrasound features, they very quickly and efficiently transmit information about the object’s current position.

Rotary encoders are special equipment that determines shaft angle rotation. The most often they are used to determine a displacement of motor shaft. Encoders are one of the key parts of control systems for industrial automation. The manufacturer produces sensors of both absolute and incremental type.

Positioning systems are designed to very accurately determine the current position and movement of measuring objects. These devices can read changes in several axes. They determine both linear and rotational movement. Pulse Ranging Technology (PRT) is widely used in such type.

Inclination and acceleration sensors accurately control speed variation. They use the new two-piece mounting concept. These systems are necessary for elevators, cranes and other systems where inclination and acceleration have a critical role in work and safety.

Industrial communication provides reliable and fast data transfer within systems. This equipment works with the most popular protocols and interfaces, including Ethernet, IO-Link and AS-interface.

Identification systems monitor the status of a stream or objects movement on conveyor belts. Different models operate with different frequency ranges. The manufacturer produces devices with Radio Frequency identification or Optical one.

Displays and signal processing equipment quickly convert and count digital and analog signals. They greatly simplify the data monitoring. In addition to the main equipment groups, Pepperl Fuchs also manufactures devices for connectivity and accessories. These categories include connectors, cables, switches and a wide range of parts for the main series.

Pepperl + Fuchs pays great attention to production of explosion protection. This category includes various systems for operating in harsh and hazardous environments. It provides reliability and safety throughout the entire life cycle.

Pepperl + Fuchs has more than half-century of experience working with sensors. During this time, the company released numerous product series, including innovative ones. For thousands of its users, P + F sensors are synonymous with precision and reliability.